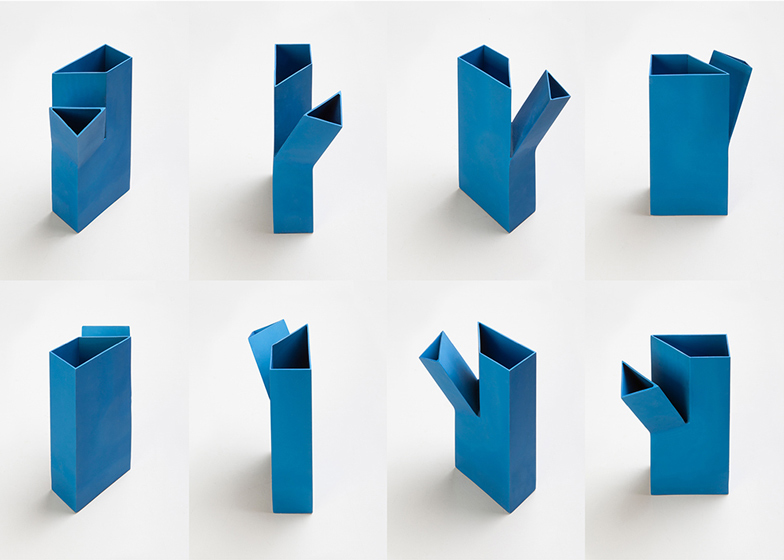

These metal carafes by Amsterdam-based designer Michael Schoner look as if they have been chopped to create a spout (+ slideshow).

Prototyped and welded in Istanbul by local craftsmen, Schoner's Chop Carafe features an angular spout that sits at a 30-degree angle to the main body of the carafe.

Schoner told Dezeen about working with small Turkish manufacturers: "Handcraft in Turkey is affordable and little workshops are very willing to work together."

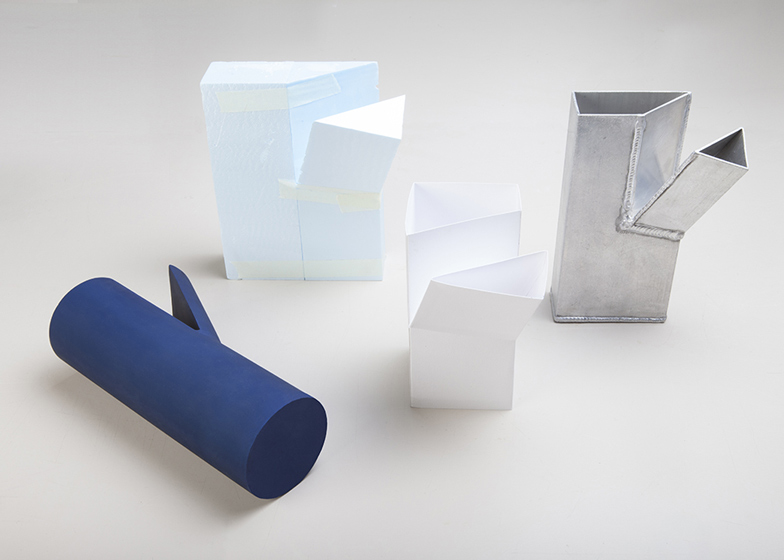

The carafes are cut from industrial aluminium pieces with circular or rectangular profiles.

A section is removed to create an edge for attaching the spout, which welded on along with a base and a piece to fill the remaining gap to create the final shape.

The welded joints are smoothed out and the product is coated for use with liquids such as wine, water or juices.

The rectangle-shaped design comes in two versions for right and left-handed use, depending on which corner the spout is attached. Photography is by the designer.

Here is some more information from Schoner:

Chop Carafe

The Chop Carafe is based on the observation that if one takes a volume it can be cut in and fold it out to create a snout. The carafes are made from standard aluminium profiles as used in the building industry. The profiles are cut in and a segment is removed. Adding a bottom- and a “V” shaped plate the parts are then welded together into the final shape.

After grinding and pearling they are anodised and coated against fruit acids. The carafes hold between 0,7 to 1,0 litres and are made for liquids like wine, water or juices. There are three different basic shapes based on round, square and rectangular aluminium profiles.

The spout folds out 30 degrees. Since on the square and rectangular carafe they fold out diagonally one ends up with an either left-handed or right-handed version. The project was born out of a foam-cutter logic that is often used in contemporary architecture and with a CNC pipe-cutter in mind. From first idea to status quo two years have passed.

First tryouts where done in Amsterdam, but on a trip to Istanbul the prototyping was solved in an pleasant ad-hoc mentality of local craftsmen in September 2012. In a team play between a local profile shop, a work-shop specialised in cutting and a old local welder in the district of Çağlayan, all found at the local bar, the prototypes were ready within 24 hours.