World Architecture Festival 2015: bamboo could "revolutionise the building industry" and replace steel as the dominant reinforcing material, according to a professor who is working on new applications for the grass.

Speaking at WAF in Singapore today, Dirk Hebel said that bamboo fibre could be used as a more sustainable and far cheaper alternative to steel on construction sites.

"This has the potential to revolutionise our building industry and finally provide an alternative to the monopoly of reinforced concrete," Hebel said.

Hebel, a professor at the Swiss Federal Institute of Technology Zurich (ETH), has developed a new material made of bamboo fibres mixed with organic resin.

The material, called bamboo composite material, can be pressed into any shape and then sawn or sanded like wood.

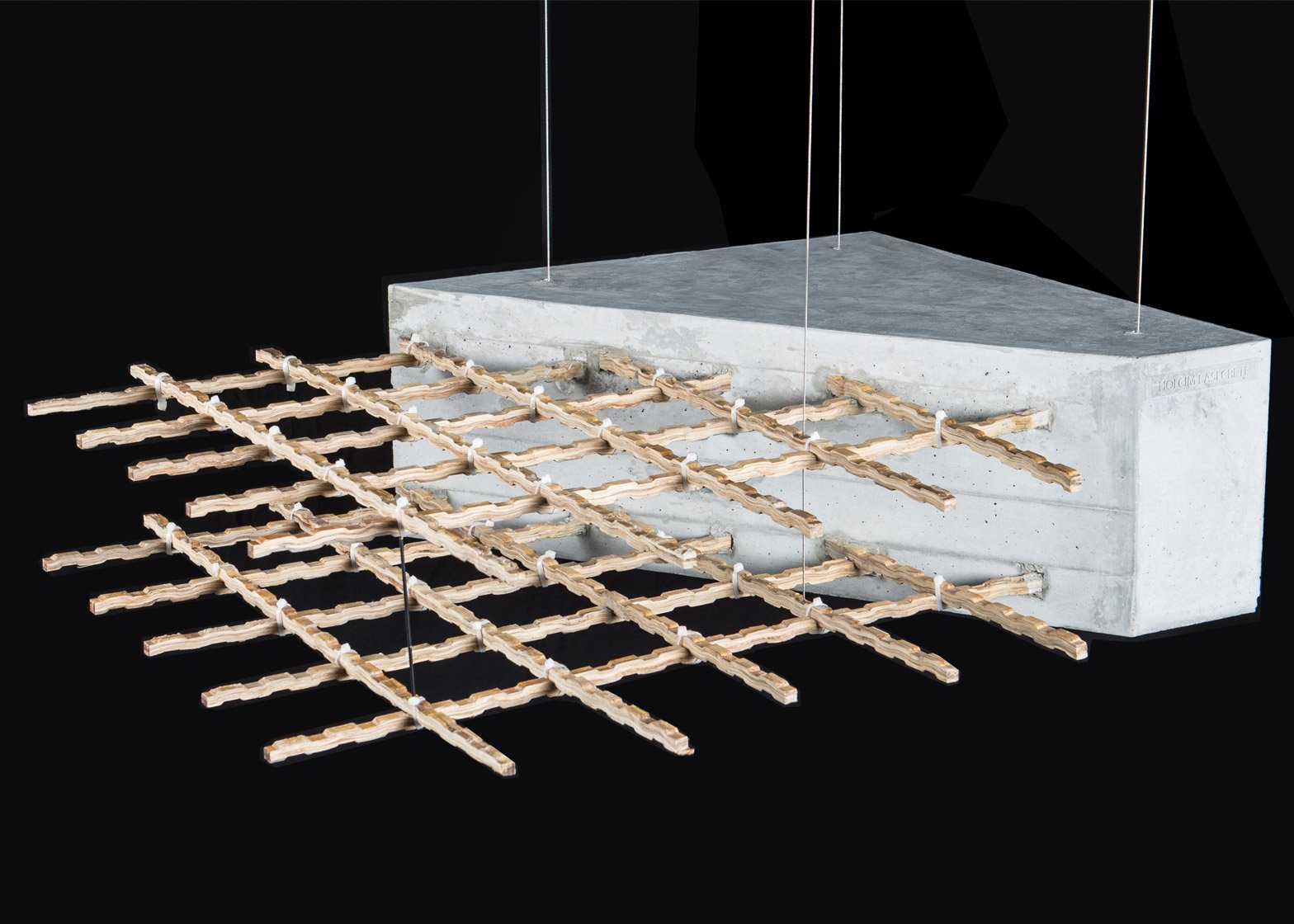

Formed into rods, the material could potentially replace steel as a reinforcing matrix for concrete with no loss of performance, according to Hebel.

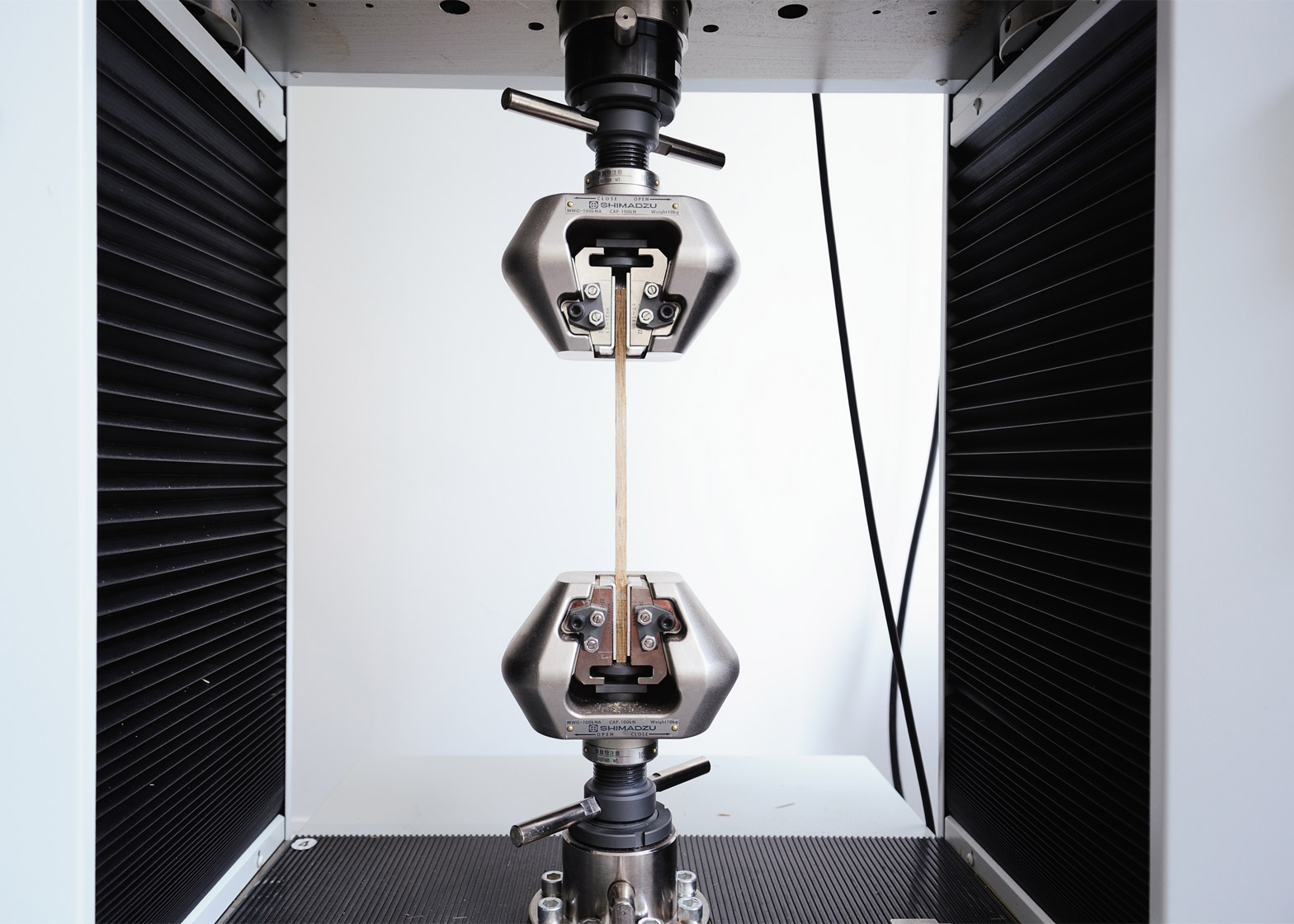

"We can produce a material that in terms of tensile capacity is better than steel," Hebel said. "Our material is only a quarter of the weight of steel. In terms of strength to weight, it performs better than steel."

Hebel said the material could also be used for other industrial applications, for example in the automotive industry.

"The material could also be used for car body parts," he said. "The big advantage of a bamboo fibre is that it is 100 times cheaper than carbon fibe, but it has potentially the same strength."

He added: "We started out looking for a replacement for steel but the field of applications is becoming wider."

Hebel started experimenting with bamboo as part of a research project to give developing countries more sustainable and affordable alternatives to steel, which has to be imported from producing countries that are mostly in the developed world.

According to Hebel, 70 per cent of all steel and 90 per cent of all cement is consumed in developing countries.

"We found one very interesting plant that grows exactly in those areas where we expect the highest urbanisation rate," he said. "That plant is bamboo."

Bamboo, which has extremely high tensile strength, has long been used as a construction material in the developing world. But rather than use bamboo in its natural state, Hebel developed a way of extracting fibres from the plant and mixing it with 10% organic resin to create a mouldable material.

Concrete reinforced with the material has been undergoing testing at a laboratory in Singapore. "Yesterday we had a breakthrough – our testing machine was not able to break the material," Hebel said.

Unlike timber, bamboo does not require replanting after harvesting. As with other grasses the root system remains in the ground, stabilising the soil while new shoots are generated.

Last year, Vietnamese architect Vo Trong Nghia, who has built many projects using bamboo, told Dezeen the grass would be "the green steel of the 21st century."

The architect is part of a new movement that is putting bamboo construction back in the spotlight, with well known firms like Kengo Kuma and Shigeru Ban experimenting with the material. Beijing- and Vienna-based Penda has developed proposals for bamboo hotels and even entire modular cities made from the material.

Bamboo is also being used increasingly for disaster-relief construction projects, thanks to its strength, low cost and wide availability. Examples include shelters for earthquake victims in Nepal, temporary accommodation for Burmese refugees in Thailand, and flood-resistant housing in Vietnam.

Hebel told Dezeen that the next step is to develop a sustainable alternative to concrete which, together with other cement products, accounts for 50% of all construction materials used globally.

"Besides bamboo we do a lot of research into other materials and of course our aim is also to replace the concrete," Hebel told Dezeen.

"So right now we are working with Berkeley University to develop an alternative to concrete that is not based on cement but on a biological based material made of mycelium [the material fungi is made of]."

Bamboo composites could potentially be used to build skyscrapers in future, Hebel said.

"Can you build high-rises with that material?" he said. "In theory you can but that is not the market we're talking. Eighty per cent of all structures worldwide are one or two stories. That is our market."

Project credits:

Research Team ETH/FCL: Felix Heisel, Mateusz Wielopolski, Alireza Javadian, Simon Lee, Karsten Schlesier, Tobias Eberwein, Philippe Mueller, Dirk E Hebel

Research Team EMPA: Tanja Zimmermann, Sebastien Josset

Rehau: Dragan Griebel