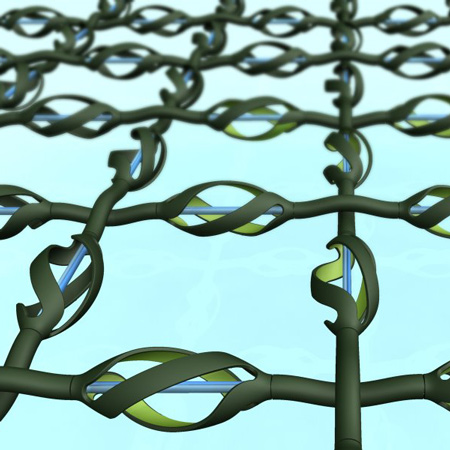

Aerogenerator X by Grimshaw and Arup

London architects Grimshaw and engineers Arup have unveiled this design for an offshore wind turbine.

Top and above images are by Grimshaw

Called Aerogenerator X, the design for British company Wind Power would produce twice as much power and have half the weight of the company's current design.

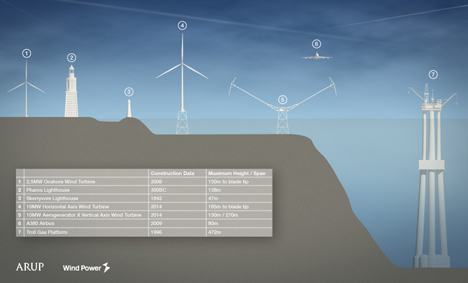

Above diagram is by Arup. Click for larger image.

Here's some more information from Wind Power Limited:

British company Wind Power Limited has unveiled the new embodiment of its innovative Aerogenerator project visualised by leading international architects Grimshaw. The Aerogenerator X is twice the power and half the weight of Wind Power’s original Aerogenerator design.

The Aerogenerator X is considered one of the only real alternative solutions available to help deliver the UK’s offshore wind strategy in a reliable and cost effective manner. It does not have the same weight constraints as a normal wind turbine and the blades do not suffer weight-induced fatigue. This new design is half the height of an equivalent horizontal-axis turbine and its weight is concentrated at the base of the structure.

The Aerogenerator X is the conclusion of an 18-month feasibility study called the NOVA project undertaken by Cranfield University, QinetiQ, Strathclyde University, Sheffield University and Wind Power Limited supported by consultant engineers and project managers. The NOVA feasibility project was funded by the Energy Technologies Institute, a public private partnership comprising BP, Caterpillar, EDF, E.ON, Rolls-Royce, Shell, BP, EDF, EON, Caterpillar, the UK Government and Wind Power Limited.

Wind Power Limited is also delighted to announce that it is in the process of entering a Memorandum of Understanding with Arup to help successfully continue project development.

Speaking at the unveiling of Aerogenerator X John Roberts, Head of Energy at Arup, said: ‘Despite the installation of a number of large wind turbines offshore, the problems of increasing capital cost for deeper water remains unsolved as does the issue of safe operability in the marine environment. There is a tremendous opportunity for new ideas to make a difference to the commercial viability and operability of offshore wind power. More cost-effective solutions will be essential if offshore wind power is to make the ‘hoped for’ contribution to the UK’s GHG emission reduction targets.’

Professor Feargal Brennan, Head of Offshore, Process and Energy Engineering at Cranfield University, said: ‘Upsizing conventional onshore wind turbine technology to overcome cost barriers has significant challenges, not least the weight of the blades, which experience a fully reversed fatigue cycle on each rotation. As the blades turn, their weight always pulls downwards, putting a changing stress on the structure, in a cycle that repeats with every rotation – up to 20 times a minute.

‘In order to reduce the fatigue stress, the blade sections and thicknesses are increased which further increases the blade self-weight. These issues continue throughout the device. Drive-train mountings must be stiff enough to support the heavier components inside the nacelle on top of the tower, otherwise the systems can become misaligned and the support structure is also exposed to extremely large dynamic thrust and bending stresses, which are amplified significantly with any increase in water depth.’

Theo Bird of Wind Power Limited said: ‘Offshore is the ideal place for wind power but is also an extremely tough environment. The US wind researchers who worked on vertical axis projects have always regarded the technology as great to work with at sea because it can be big, tough and easily managed. We are extremely grateful to the ETI who had the vision to help us pick up from where the US left off. By facilitating projects like ours they continue the heritage of great engineering in Britain.’

Neven Sidor, Partner at Grimshaw, said: ‘The Aerogenerator X embodies the best in innovative engineering in Britain, and continues an illustrious tradition. Grimshaw has great regard for this engineering tradition, and is delighted to help in its realisation.’

See also:

.

|

|

|

| Wind dam by Chetwood Associates |

Nano Vent-Skin by Agustin Otegu |

Energy Roof Perugia by Coop Himmelb(l)au |