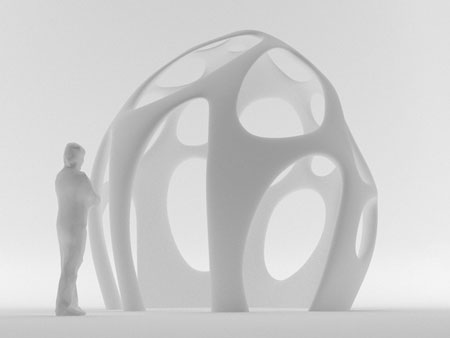

Radiolaria pavilion by Shiro Studio

Andrea Morgante, founder of Shiro Studio, has collaborated with D-Shape to produce the Radiolaria pavilion, a complex, free-form structure produced using the world's largest 3D printer.

Measuring 3 x 3 x 3 metres, the structure is a scale model of a final 10-metre tall pavilion to be built in Pontedera, Italy, in 2010.

D-Shape, the world's first large-scale stereolithic printer, was developed by Italian engineer Enrico Dini in 2008 to offer architects the design freedom that rapid prototyping allows.

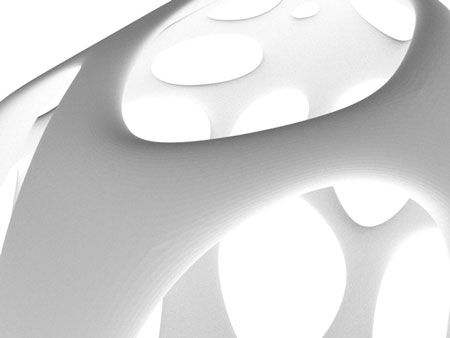

The structure is made of an artificial sandstone material and does not feature any internal reinforcement.

Held together by an inorganic binder, the resultant material has excellent strength properties - with some performance characteristics superior to portland cement - and will not damage the environment.

The structure was designed using CAD-CAE modeling technologies and CAD-CAM software controls the plotter during printing. The process starts from the bottom and proceeds in 5-10mm layers at a time.

The solidification process takes 24 hours to complete and any surplus material supports the structure during manufacture and can be reused.

Here are further details from Shiro Studio:

--

RADIOLARIA BY SHIRO STUDIO

Radiolaria represents a micro-architecture experiment developed by Andrea Morgante of Shiro Studio in association with D-Shape. In 2008 D-Shape successfully developed the very first 3D mega printer that allows seamless and free-form construction of monolithic structures on a large scale.

The Radiolaria pavilion aimed to define a complex, self-supporting structure that could demonstrate and test this pioneering construction technique. Measuring 3x3x3 meters, the structure represents a scale model of the final pavilion, due to be built in 2010; this pavilion will be 10 meters high and will be built in Pontedera, Italy.

Concept

Three-dimensional digital investigations are a constant pursue in the contemporary architectural landscape. The freedom generated by the latest modeling software, associated with the parametric/ scripting potentials, has given architects a powerful design instrument able to generate complex morphologies. Traditional rapid prototyping printers have helped designers to materialize these visions, although the results are inevitably destined to be display models only at a modest scale.

When D-Shape commissioned Andrea Morgante the design for the first large-scale structure to be printed the ultimate aim was to produce a geometry that could be self-supporting and demonstrate the capabilities of this innovative technology: being made of artificial sand-stone material and without any internal steel reinforcement the pavilion’s design and execution had to be intrinsically resilient to several static stresses. Ernst Haeckels’ studies on radiolarians and comparative anatomy has been an invaluable source of inspiration: mineral and siliceous skeletons, through a gentle, evolutionary formation process share an affinity with the way that the mega-printer operates, through the gentle, slow deposition of mineral and siliceous material, layer after layer.

The geometrical morphology of Radiolaria reflects the potential provided by the mega-printer, able to build any complex geometry without the use of provisional, temporary formwork or disposable, expensive moulds.

Technology

CAD-CAM software operates the plotter during the printing process. The external lattice structure holds the printer head, which represents the real core of this new technology. Despite its large size, the structure is very light and it can be easily transported, assembled and dismantled in a few hours by two workmen. The process begins from the 3D data: the computer design obtained is converted into an STL file and is imported into the software that controls D-Shape’s printer head. The printing process takes place in a continuous work session: during the printing of each section a ‘structural ink’ is deposited by the printer’s nozzles on the sand. The solidification process takes 24 hours to complete. The printing starts from the bottom of the construction and rises up in sections of 5-10mm each: upon contact the solidification process starts and a new layer is added.

Surplus sand that has not been embedded within the structure acts as a buttressing support while the solidification process takes place. This surplus sand then can be reused on future prints.

Material

The new material (inorganic binder + sand or mineral dust) has been subjected to traction, compression and bending tests. The results have been extraordinary and the artificial sandstone features excellent resistance properties. Effectively this process returns any type of sand or mineral dust back to its original compact stone state.

The binder transforms any kind of sand or marble dust into a stone-like material (i.e. a mineral with microcrystalline characteristics) with a resistance and traction superior to portland cement, to a point where there is no need to use iron to reinforce the structure. This artificial stone is chemically one hundred percent environmentally friendly.