Esource by Hal Watts at Show RCA 2012

Royal College of Art graduate Hal Watts has come up with a bicycle-powered electronic waste recycler that could save lives in developing countries (+ movie).

In Ghana for example, young people risk their health and pollute the air by burning electronic waste imported from Europe to reclaim the valuable copper inside.

In response to this problem, Watts has come up with a bicycle-powered waste separator that extracts copper from electronic wires without the need for burning.

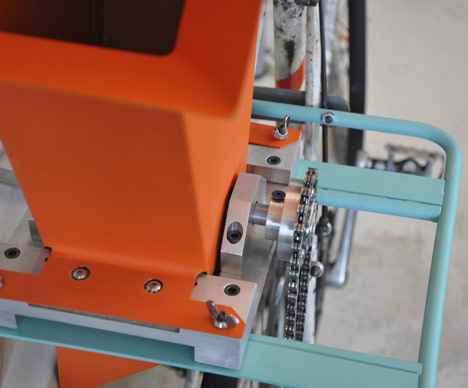

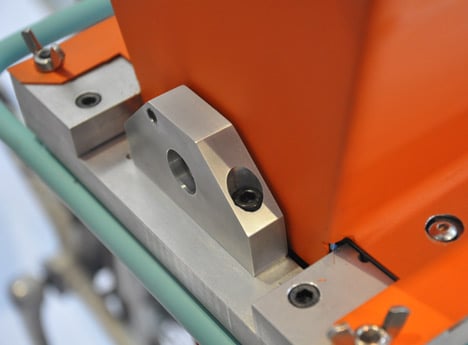

The bike is mounted on a frame so that the recycler simply pedals to power the orange shredder as it grinds wires into a mixture of plastic and copper particles.

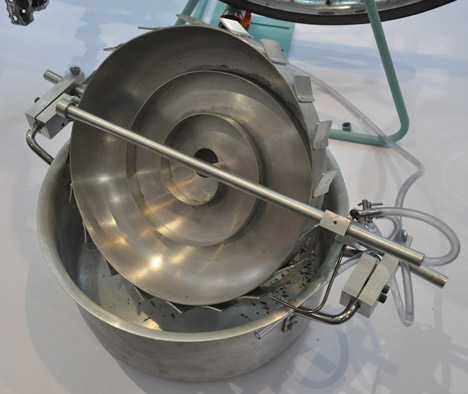

The particles then go into the metal separator, which removes the plastic and leads to a yield of 98% pure copper.

The unburnt copper can be sold for 20% more than burnt copper, while the plastic granules provide a new source of income.

Watts graduated from the college's Innovation Design Engineering course and Esource is on display at Show RCA 2012, which continues until 1 July.

See more stories from Show RCA 2012 here and watch course leader Miles Pennington give a tour of the show here.

Here's some more information from the designer:

The Problem:

Electrical and electronic waste (WEEE) is the fastest growing waste stream worldwide. The UK illegally exports 70% of its WEEE, largely to the west coast of Africa. One of the biggest centres for WEEE imports is Accra in Ghana, where some 40,000 people are dependant on informal recycling.

One of the worst practices in Accra is the burning of electrical wire to get rid of the insulation and recover the copper within. This is mostly carried out by teenagers and has terrible consequences on their respiratory and immune systems, it also leads to dioxin releases equivalent to 15% of the whole of Europe.

The solution:

Esource provides a sustainable cable recycling system for small scale recyclers in developing countries. It consists of an innovative bicycle powered cable granulator and a novel approach to separating copper and plastic using water. The machines are designed to be manufactured and maintained in country.

Un-burnt copper can be sold for up to 20% more than burnt, providing a better income for workers and much healthier working conditions. The designs will be made available to local workshops who would produce and sell the machines to recyclers creating a system that would be economically driven to spread.