R18 Ultra Chair by Clemens Weisshaar and Reed Kram

Design Miami: design duo Clemens Weisshaar and Reed Kram have used technology from the car-racing industry to develop a chair made by robots that weighs just 2.2 kilograms (+ movie).

Clemens Weisshaar and Reed Kram worked with experts at Audi's Lightweight Design Centre to produce the R18 Ultra, a chair named after and inspired by Audi's ultra lightweight prototype race car.

"We started using technology that you find in [the R18 Ultra] car and translated it into a piece of furniture, which is quite exciting because we got access to technology the furniture industry can’t even dream of," Weisshaar told Dezeen at Design Miami.

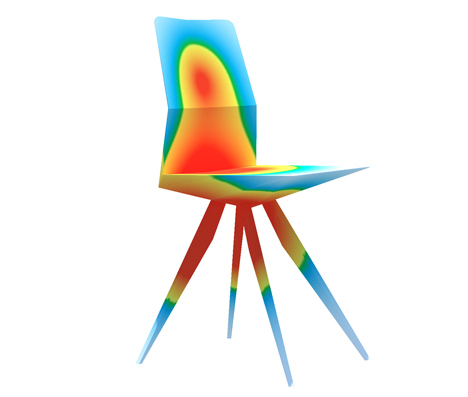

Earlier this year Dezeen reported on the public beta testing for the R18 Ultra, where hundreds of visitors to the Milan furniture fair sat on the chair while it was hooked up to advanced stress-analysis sensors.

"It’s a process somewhat borrowed from the testing and development of a racecar," said Kram. "Sitting is a very dynamic activity, weirdly, and everybody uses the chair differently," added Weisshaar. "So simply putting weight on it and doing static load tests doesn’t get you anywhere. You actually need people to engage with it."

Using data from the public beta testing, the designers worked out where they could trim off unnecessary weight from the carbon-fibre shell. "The nature of composite is it’s always a layering process," said Weisshaar."That also allows you to just take off layers where you don’t need the material.

"It’s completely different from any subtractive manufacturing or moulding, where you have a continuous wall thickness and continuous materiality. Here, not only can you manipulate the wall thickness, you can also manipulate the materiality."

The legs of the chair are cut out from flat sheets of aluminium and then put together using the same cold metal transfer technology that Audi uses to make cars.

"They’re mass production techniques," said Weisshaar, "but there are even more exciting mass production techniques in the making in the labs, which we couldn’t use because they’re totally locked away and top secret. So what we’re showing here is what’s happening tomorrow – but what’s happening the day after tomorrow is even more exciting."

In 2010 Kram and Weisshaar worked with Audi to install eight robotic arms in London's Trafalgar Square, where they spelled out messages in mid-air.

Dezeen was in Miami last week reporting on all the highlights of the Design Miami collectors fair, including the sausage-shaped inflatables around the fair's entrance, an "ice halo" of Swarovski crystals and an installation of perfect natural curves inspired by the art nouveau history of a champagne maker – see all our stories about Design Miami.

See all our stories about Kram and Weisshaar »

See all our stories about chairs »

Here's some more information from the designer:

R18 Ultra Chair

designed by by Clemens Weisshaar and Reed Kram

for Audi

December 5-9, 2012

Design Miami/

Miami Beach, FL, USA

Clemens Weisshaar and Reed Kram have developed a chair using methods borrowed from the future of automotive manufacturing in collaboration with Audi's Lightweight Design Center. The chair's multi-material space frame is made from carbon composites, carbon micro-sandwich and high strength aluminum and weighs only 2.2 kg or 77 ounces. The chair embodies Audi's ultra lightweight design credo completely by following strict guidelines to shave off every ounce of excess weight.

The R18 Ultra Chair's genesis incorporates crowd-sourced data acquired through thousands of testing sessions held in Milan during the Salone Internazionale del Mobile in April 2012. Using advanced physics simulation software, the big data set enabled designers and engineers to analyze a wide variety of load scenarios and carefully adjust and optimize the carbon fiber lay up, geometry and dimensions of the final object accordingly.

At Design Miami/ the chair's designers and engineers are giving visitors an intimate insight into their studios and labs, displaying drawings, samples, models, mock-ups, moulds and prototypes from the various stages of the development process. This includes an industrial welding robot and the chair's namesake and inspiration, the R18 Ultra - the pace car for an entire technology: Audi ultra.

Audi ultra stands for state of the art lightweight construction, technology and design aimed at streamlining and optimizing efficiency across the board. This begins with the raw materials sourced for production all the way through various manufacturing stages, the operation of the vehicle, its fuel consumption and its deconstruction and recyclability at the end of its life cycle.

Aluminum is a key material in Audi’s repertoire of lightweight design technologies: The chair’s legs are made of folded sheet aluminum, welded by an industrial robot using a cold metal transfer process. The chair’s seat shell is fabricated from the latest carbon composite materials: a combination of carbon micro-sandwich and carbon rubber composites extrapolated directly from components of the racecar. The R18 Ultra Chair manifests Audi’s ultra lightweight design credo in a 2.2 kg (77oz) piece of furniture that is ultra light and extremely durable.