Ripple table by Benjamin Hubert

London Design Festival 2013: London designer Benjamin Hubert claims to have created the world's lightest timber table and is showing it off at the Aram Gallery in London this week (+ movie).

Benjamin Hubert worked with Canadian manufacturer Corelam to develop the table, which is 2.5 metres long, one metre wide and weighs just nine kilograms.

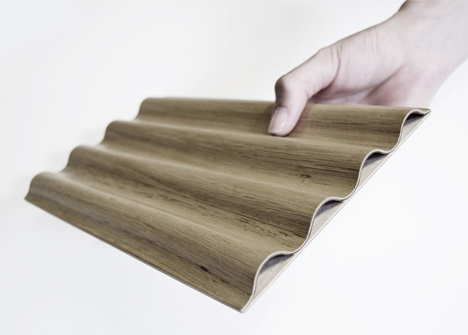

The structure was made by corrugating three layers of 0.8 millimetre-thick birch aircraft plywood. The edge of the table is just 3.5 millimetres thick.

The corrugated wooden structure is covered with a plain sheet to give a flat top, while the A-frame legs are made from a sandwich of two corrugated layers.

"Made using 70-80 percent less material than a standard timber table, Ripple can be assembled and manoeuvred by a single person," Hubert said.

Ripple will be launched at the Aram Store in London's Covent Garden as part of a solo exhibition of Hubert's work taking place during the London Design Festival.

Benjamin Hubert has also designed a chair made from lightweight woven mesh and aluminium that weighs just three kilograms, another chair with a seat and back formed from a single curled sheet of plywood, and a series of tables made from expanded steel mesh – see more products by Benjamin Hubert.

See all our stories about London Design Festival 2013 »

See Dezeen's map and guide to London Design Festival 2013 »

Here's a project description from the designer:

Ripple: Benjamin Hubert Research

Benjamin Hubert has designed the world’s lightest timber table as part of an internal studio research project into lightweight constructions. The table, titled Ripple, is 2.5 metres long, 1 metre wide, and weighs just 9 kilograms. Made using 70-80% less material than a standard timber table, Ripple can be assembled and manoeuvred by a single person.

The table's impressive strength to weight ratio is enabled by an innovative production process of corrugating plywood for furniture through pressure lamination, which was developed by Benjamin Hubert with Canadian manufacturer Corelam.

Ripple is made entirely from 3 ply 0.8mm birch aircraft plywood, a timber sourced only in Canada, where the table is manufactured. The material is the same as that used in construction of the Hughes H-4 Hercules – popularly known as the "Spruce Goose" – the world’s largest all timber airplane. The strength of the material in combination with the unique lamination process means the edge of Ripple measures just 3.5mm.

Ripple is minimal in its design language, employing a simple knockdown construction. The top surface is corrugated plywood overlaid by a flat sheet, and the A-frame legs are a sandwich construction of two corrugated plywood layers.

Ripple will be launched at Aram Store during London Design Festival in September as part of Benjamin Hubert’s inaugural UK solo exhibition, Antecedents. It will be available to buy from September on commission through Benjamin Hubert.

Material: Canadian Spruce 0.8mm aircraft plywood

Dimensions: L2.5mxW1mxH0.74m