3D-printed perfume tools by Unfold and Barnabé Fillion

Belgian design studio Unfold has created a set of 3D-printed ceramic tools for diluting and diffusing the scents of French perfumer Barnabé Fillion (+ slideshow).

Using a ceramic 3D-printing technique the studio originally developed in 2009, Unfold produced a series of objects to dilute the perfume plus a diffuser that absorbs the liquid and dissipates the scent.

"The whole setup is an olfactory installation that explores the extraordinary way in which ceramics absorb, store and release a perfume's head, heart and base notes over a prolonged time," Dries Verbruggen of Unfold told Dezeen.

The printed tools include a carafe that holds distilled water, a smaller receptacle for alcohol and a high-necked flask, pipette and funnel used to dilute and mix the perfume.

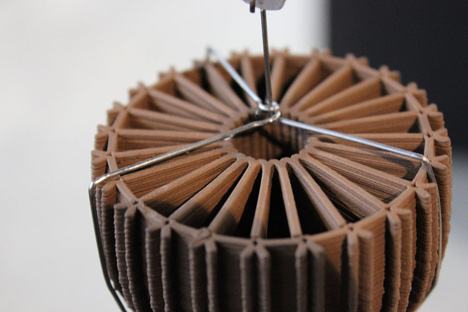

Diluted perfume is then poured into the central core of an unglazed diffuser and gradually spreads through the multiple compartments, which create a greater surface area to absorb the liquid.

"The inspiration here was taken from fruit cut-throughs," said Verbruggen. "When you cut through a lemon for example, you release its essence in the atmosphere but you also expose the intricate inner structure of the fruit."

Although the diffuser will naturally release the perfume's scent over time, the designers created an apparatus that spreads it around, "to give it an extra punch and to add a conscious gesture."

Any of three different diffusers can be attached to an oak and aluminium contraption and are counterbalanced by a weight. Turning a handle causes the diffuser to rotate, releasing the scent as it spins.

The items are printed from fine layers of ceramic that produce a stratified surface. "The technique is very suited for intricate and complex ceramic shapes like the diffusers," Verbruggen explained. The vessels have a layer thickness of one millimetre that results in a rough surface, while the more precise diffusers are formed from 0.5 millimetre-thick layers.

Unfold created the installation for the launch of Barnabé Fillion's perfume brand, which is called The Peddler and focuses on the experience of scent through temporary events and exhibitions. Their machine was one of several collaborations Fillion undertook with artists and designers, and he presented the results at Maison & Objet in September.