Advances in design software mean "materials are becoming media"

Dezeen and MINI Frontiers: new technologies mean the design process is becoming akin to "creating a Hollywood film," says designer Francis Bitonti, who created a seamless 3D-printed dress for burlesque dancer Dita von Teese.

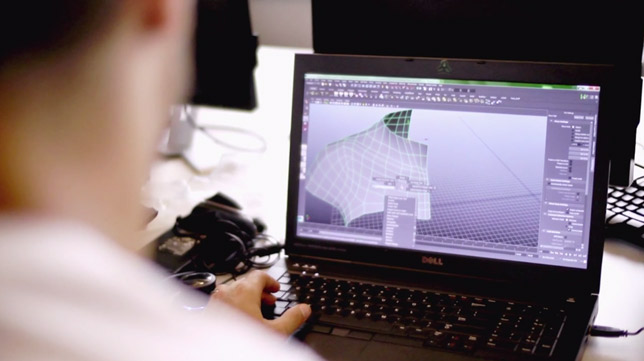

Speaking about the development of the dress at the Wearable Futures conference in London in December, Bitonti says that developments in computer-based design and 3D printing mean that designers are no longer limited by their knowledge of materials.

"The separation between what you can simulate and what you can physically model is gone", claims Bitonti, founder of New York luxury fashion studio Francis Bitonti Studio.

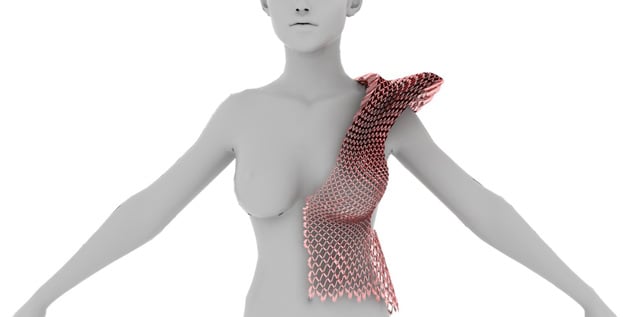

Von Teese premiered the 3D-printed dress designed by Bitonti and designer Michael Schmidt at the Ace Hotel in New York in March last year and it became one of the most talked-about fashion stories of the year.

"One of the things we’ve been noticing is that materials are becoming media. I’m not operating on materials, I’m operating on animations, I’m operating on video, I’m operating on pixels and polygons. [The design process] is a lot closer to creating a hollywood film than it is making an aluminium cylinder," says Bitonti.

Possibilities are now limited by the designer’s imagination rather than material constraints, Bitonti says. "What I’m finding every day is that I can make anything I can draw. And I can make something behave any way I can imagine it behaving. The gap closes every day."

Prior to launching Francis Bitonti Studio, Bitonti trained as an architect. He says this background proved useful when designing the figure-hugging dress for the American model and burlesque dancer Dita von Teese.

"I found that developing a second skin for the body wasn’t really that much different from thinking about a building facade. It’s about breaking up shapes in pretty much the same way," he says.

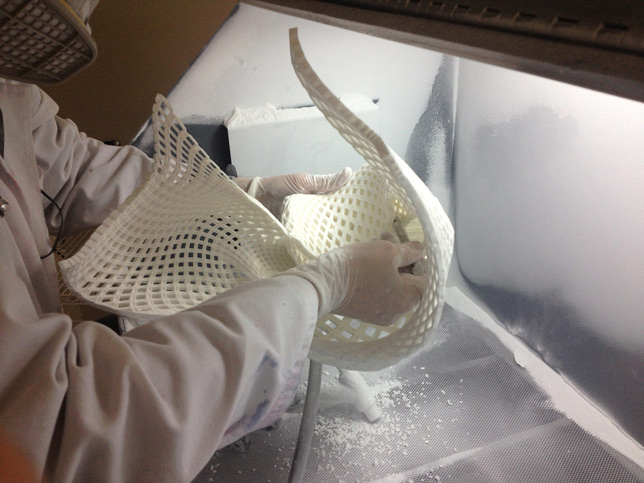

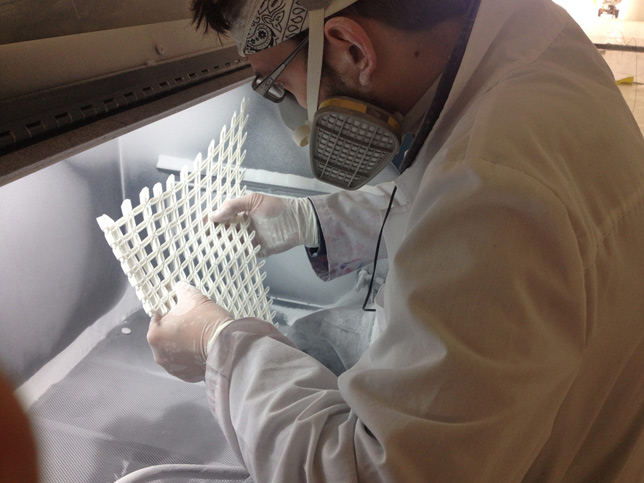

The seamless dress, which he developed last year, was made out of 3000 unique moving parts made using selective laser sintering (SLS), where material is built up in layers from plastic powder fused together with a laser.

The two-day Wearable Futures conference explored how smart materials and new technologies are helping to make wearable technology one of the most talked-about topics in the fields of design and technology.

Bitonti is not the only designer exploring the fashion possibilities of 3D-printing.

Last year fashion designer Iris van Herpen and shoe designer Rem D Koolhaas collaborated to create 3D-printed shoes that look like tree roots and creative director of 3D Systems Janne Kyttanen designed a range of 3D-printed shoes for women that can be made at home overnight to be worn the next day.

The music featured in the movie is a track by DJ Kimon. You can listen to his music on Dezeen Music Project.

Dezeen and MINI Frontiers is a year-long collaboration with MINI exploring how design and technology are coming together to shape the future.