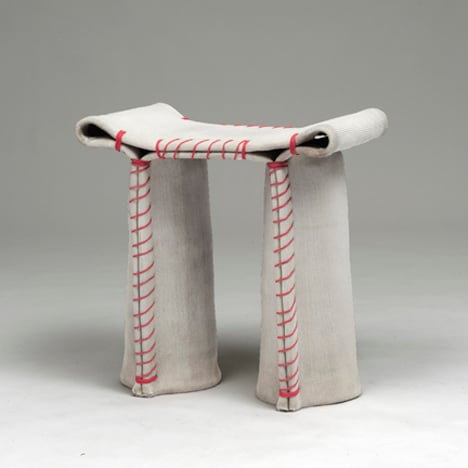

Stitching Concrete by Florian Schmid

Industrial design graduate Florian Schmid made these stools by folding fabric that's impregnated with cement then drenching it in water.

Called Stitching Concrete, the stools are made from a material called Concrete Canvas, which Dezeen featured in 2009.

It consists of cement layered between fabric and a PVC backing. Once soaked it can be manipulated for a few hours before hardening.

Schmid folds the Concrete Canvas and stitches the edges together with brightly coloured thread, then supports it on a wooden mould while it's drenched in water and allowed to harden.

The finished stools retain the soft appearance of folded fabric but are fireproof, waterproof and strong enough to sit on.

Schmid developed the project while studying at the Hochschule München in Germany.

Read more about Concrete Canvas, including applications for disaster relief, in our earlier story.

The following information is from Florian Schmid:

Stitching Concrete

"Stitching Concrete" is inspired by the contrasts of the Material Concrete Canvas.

Once brought in the final shape, you just have to water the material and within 24 hours it will harden out. It combines the warm softness of the cloth and the stability of the cold concrete.

The project plays with a visual delusion that actually an 8mm thickness of cloth can not give the strength to sit on.

After some first test how to handle the material I tried to approach through different channels like patterns, stitchings, and all kinds of origami. For the final mock-ups thin foam rubber simulated the abilities of the real material as best.

A special build wooden rack used as mould gives hold to the material during the watering and drying process. After the stool is harden out it can be removed.

The mould is always the same and adjustable to the different heights, lengths and width of the objects.

The Stools are for indoor and outdoor use, caused by the material's durability against UV, fire proofed, water resistant and more.