Benjamin Hubert's lightweight Ripple table is now strong enough to stand on

British designer Benjamin Hubert has developed a more stable version of his lightweight Ripple table, which features on the shortlist for Designs of the Year 2014 (+ slideshow).

Hubert launched the original Ripple table during last year's London Design Festival to demonstrate the structural capabilities of a lightweight laminated plywood material called Corelam.

The nine kilogram product was described as the world's lightest table, but attracted criticism from Dezeen readers who wondered whether it was robust enough for practical use.

"I can't imagine this is very sturdy - at 2.5 metres long it looks and feels too flimsy," said one reader, while another suggested: "You should prove stability, not lightness."

In reaction to doubts over the product's practicality, Hubert and his team performed a series of strength and stability tests before overhauling the design to improve its structural properties. It is now strong enough to hold the weight of a person.

"I think it's important to make products that really work," Hubert told Dezeen. "A concept always needs to be proven, and we enjoy healthy criticism as it pushes us to go further."

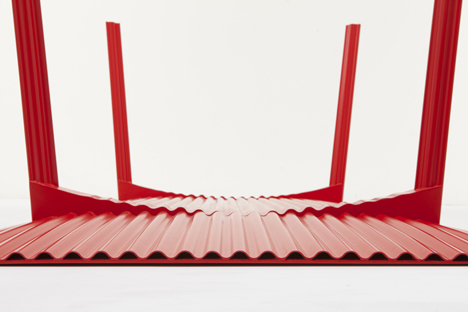

The updated version features a curve across the underside of the table surface that increases its tensile strength, as well as a new leg design with a triangulated cross section.

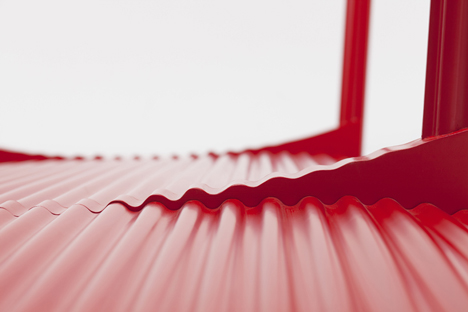

A brace attaching the legs to the tabletop is also made from Corelam. This has been pressed to produce an undulating profile that creates a transition between the corrugated surface and the flat area to which the legs are fixed.

Up to ten people people can be seated around the 2.5 by 1 metre table, which uses 80 percent less material than a standard timber table and still weighs just 10.5 kilograms

In direct response to comments suggesting that the original table should have been shown with someone standing on it to demonstrate its strength, Hubert has done just that with the new version.

The Ripple table is on show as part of the Designs of the Year exhibition at London's Design Museum, which opens today and runs until 25 August.

Here's a press release from Benjamin Hubert:

Ripple 2.0

Held by 1. Holds 1. Seats 10.

Ahead of the Design Museum's Designs of the Year 2014, Benjamin Hubert Ltd has launched the production-ready version of the nominated Ripple table, which is now also available for purchase through Benjamin Hubert Ltd. The table can still be assembled and manoeuvred by a single person but can now easily support the equivalent of a person’s weight, further demonstrating the properties of the lightweight construction.

Following a series of rigorous strength and stability tests undertaken by the studio, the underside of the table's surface now curves gently across its length and width, adding tensile strength to the structure. The improved leg design now employs a hollow triangular profile that offers increased strength and rigidity in two directions. The brace between the legs has a curved cross section to increase the strength of the connection between the leg and the table surface. As the corrugated plywood meets the legs, it gradually transitions to a flat surface, providing a smooth intersection.

Ripple uses 80% less material than a standard timber table, and at 2.5 metres long and 1 metre wide, it now offers ample space for ten place sittings. The table's impressive strength to weight ratio is enabled by an innovative production process of corrugating plywood for furniture through pressure lamination, which was developed by Benjamin Hubert Ltd in collaboration with Canadian manufacturer Corelam.

Ripple is made entirely from 3 ply 0.8mm sitka spruce, a timber sourced only in Canada, where the table is manufactured. The engineered timber was also used in construction of the Hughes H-4 Hercules – popularly known as the "Spruce Goose" – the world's largest all-timber airplane. The strength of the material in combination with a unique lamination process means the edge of Ripple measures just 3.5mm.

Ripple was designed as part of an internal studio research project into lightweight constructions, and was first launched at Aram Store during London Design Festival last year. Ripple will be exhibited as part of the Design Museum's Designs of the Year 2014.

Material: Sitka Spruce 0.8mm aircraft plywood

Dimensions: L 2.5m x W 0.95m x H 0.74m