NASA 3D prints its first object aboard the International Space Station

News: a 3D printer on the International Space Station has produced its first object, "paving the way to future long-term space expeditions" according to the US space agency NASA.

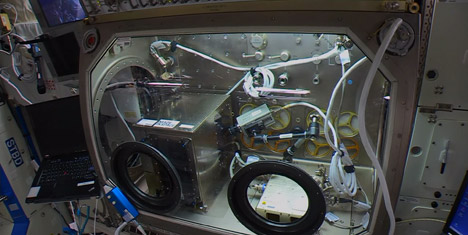

Installed on the space station on 17 November by NASA astronaut Barry Wilmore, the printer began producing its first part – a faceplate for its own casing – on Monday using commands sent from ground controllers on earth. The experiment was intended to prove that the machine would be able to produce its own replacement parts in space.

"This first print is the initial step toward providing an on-demand machine shop capability away from Earth," said Niki Werkheiser, project manager for the International Space Station 3D Printer at NASA's Marshall Space Flight Center in Alabama. "The space station is the only laboratory where we can fully test this technology in space."

"If a printer is critical for explorers, it must be capable of replicating its own parts, so that it can keep working during longer journeys to places like Mars or an asteroid," added Werkheiser. "Ultimately, one day, a printer may even be able to print another printer."

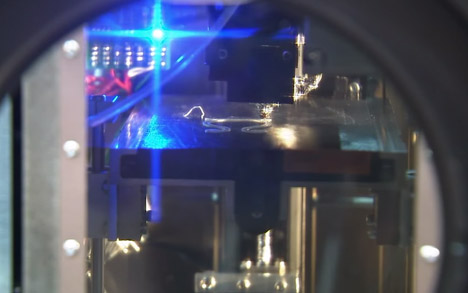

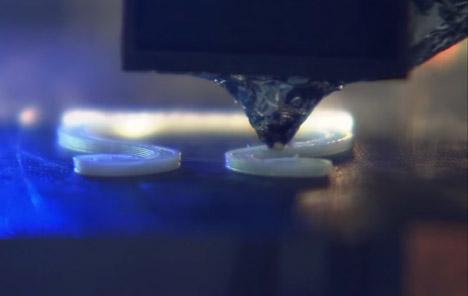

NASA's printer produces objects by extruding plastic filament that has been heated at a low temperature to melt it. The plastic is printed in layers, slowly building an object using digital design data that is sent to the machine.

The first object was removed from the machine yesterday morning and inspected by Wilmore, who found that it had partially stuck to its tray. The NASA team said this suggested that the bonding of the layers of plastic might be different in microgravity.

A new printer tray has now been installed, and a new printing instruction sent to the machine by the ground team. These first objects printed in space will be sent to Earth next year to be compared to control samples and see if there are any differences between the printing quality achieves in microgravity and in normal ground conditions.

"This is the first time we've ever used a 3D printer in space, and we are learning, even from these initial operations," said Werkheiser. "As we print more parts we'll be able to learn whether some of the effects we are seeing are caused by microgravity or just part of the normal fine-tuning process for printing. When we get the parts back on Earth, we'll be able to do a more detailed analysis to find out how they compare to parts printed on Earth."

The faceplate produced by the first print run is engraved with names of the organisations that collaborated on the project: NASA and Made In Space, Inc, the space manufacturing company that worked with NASA to design, build and test the 3D printer.

Teams from both organisations are monitoring the printing processes from the ground using images and videos beamed back from the space station, which is in orbit 431 kilometres above Earth.

The printing process is controlled from Earth to make it a more efficient process and limit the amount of time needed for astronauts to spend on the project.

"The operation of the 3D printer is a transformative moment in space development," said Aaron Kemmer, chief executive officer of Made In Space. "We've built a machine that will provide us with research data needed to develop future 3D printers for the International Space Station and beyond, revolutionising space manufacturing. This may change how we approach getting replacement tools and parts to the space station crew, allowing them to be less reliant on supply missions from Earth."

This week's experiments take NASA a step closer to its ultimate ambition – to be able to generate large, complicated structures in space.

Last year the space agency revealed it was in the process of developing an orbiting digital fabrication factory, which would allow it to use robots and 3D printers to build giant structures such as antennas and solar arrays of up to a kilometre in length while in space. Technology firm Tethers Unlimited Inc (TUI) was awarded the contract to work on the facility.

The European Space Agency is also working on ambitious extraterrestrial 3D printing plans, working with architecture firm Foster & Partners to explore the possibilities of 3D printing buildings on the moon using lunar soil.