Modern Synthesis uses bacteria to create biomaterial fabric

Biotechnology company Modern Synthesis has developed a biomaterial from bacterial fermentation that can be used to create a low-carbon alternative to traditional clothing fabrics.

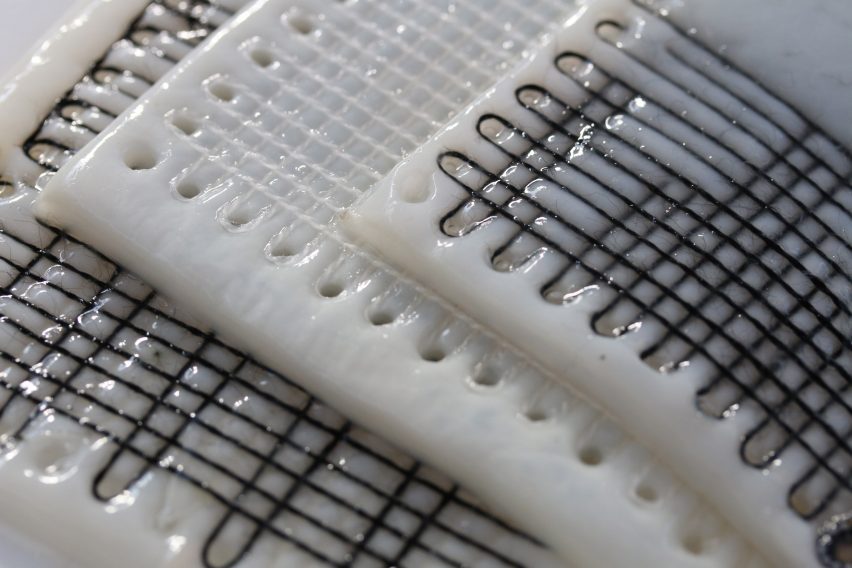

The biomaterial was developed in the company's London lab by growing the nanocellulose – a lightweight material produced by bacteria – on a framework of thread to create a new type of fabric.

"Our process is quite unique," Modern Synthesis founder Jen Keane told Dezeen. "We take waste feedstocks, so sugars from a variety of sources – this could be fruit waste or other agricultural waste – and the bacteria grow on that sugar and naturally produce nanocellulose."

Nanocellulose fibres, which are very small, are eight times stronger than steel and stiffer than Kevlar, according to the designer.

"They're really strong fibres and they're so small that when they stick to themselves, because of their structure, they create these strong bonds," Keane explained.

"So you get a really strong, lightweight material."

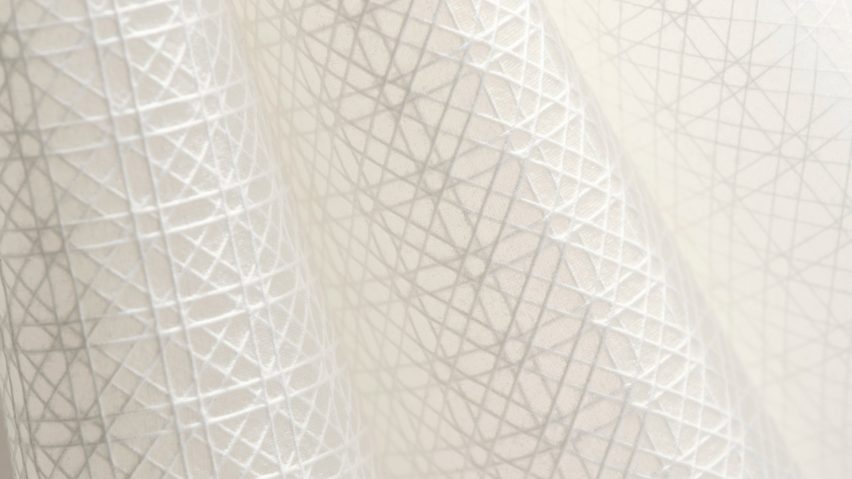

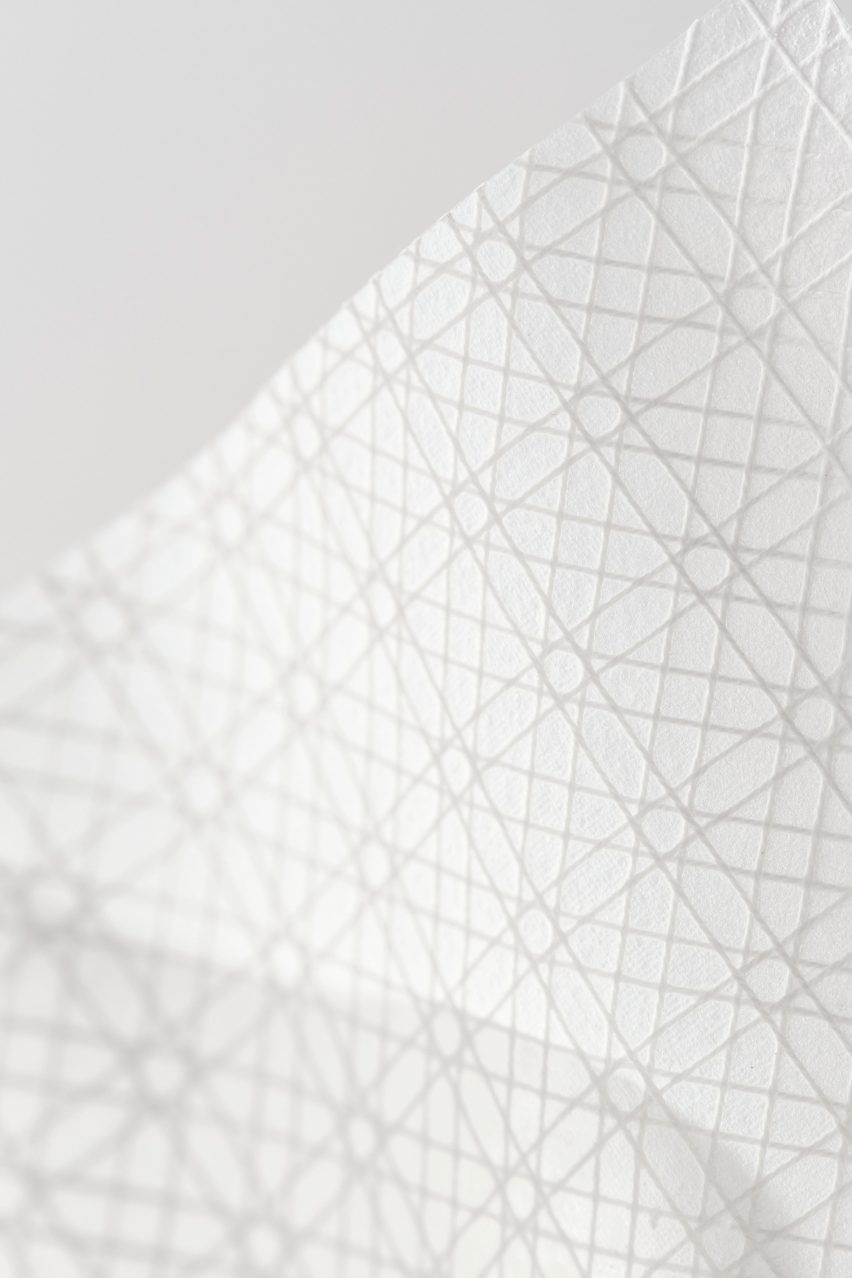

Modern Synthesis grows the nanocellulose on a framework of thread to create a material that looks similar to nylon, ripstop or a coated textile, but feels dry and warm like cellulose or paper to the touch.

"We're able to create this new material that is partially a traditional textile and partially a biofilm – a hybrid, nonwoven composite material that is really fundamentally different than anything else that exists at the moment," Keane said.

"It drapes almost like a skin or leather; there's a real mesh of different haptics, which is where I get really excited."

The process of creating the material can be adjusted by using different types of thread as the framework, some of which will be able to biodegrade while others can be recycled in a similar way to other cellulose.

"At every stage, you can make changes that then change the material fundamentally," Keane said.

"On a material level, by changing the way that the bacteria come together or how much fibre you put in it, you can change the thickness of the drape and its stiffness; by changing the textile, you can change the texture and the structure and the handfeel," she added.

Modern Synthesis believes that the biomaterial could become a versatile alternative to traditional textiles as it can be dyed and given different coatings.

The company believes that this could help minimise the carbon impact of the clothing industry, as the material creates "significantly less" emissions than traditional textiles.

"Think about how a natural textile is made today: you have a field of cotton, it's there for months and you put an incredible amount of water in it," she said.

"There's a lot of resources that go into creating that cotton, and then you have the energy that it takes to transform that into a fibre or into yarn," Keane added.

"Here you are literally, at the simplest level, taking a waste sugar and transforming that into a material in far less steps. The energy in the steps that go into that chain is a lot less."

Keane, who worked at Adidas for several years before founding Modern Synthesis together with synthetic biologist Ben Reeve, had previously created a "bespoke" prototype trainer using this kind of biomaterial.

"We've prioritised taking what started as a very bespoke craft process that I developed during my MA at Central Saint Martin's and redesigning that, picking it apart and looking at how the different elements of the process scale," she said.

"Bacteria cellulose is already scaled for other industries so there is a wealth of knowledge on the biological side that we can pull from," Keane added.

"It's used in bio-cellulose facemasks, there's kombucha and nata de coco, which is a desert in Asia – it's the same organism, just a slightly different process."

Modern Synthesis just opened a new laboratory in Balham, south London, and hopes that its biomaterials will soon be used by the wider industry.

"What we're trying to communicate to the wider world is the potential and the adaptability of these materials, which is what's really exciting," Keane concluded.

"We're not trying to just make another leather – it's really an exciting new textile category and a huge opportunity for the fashion industries and other industries to rethink materials."

Other recent fashion projects using biomaterials include a jumpsuit by Stella McCartney and a handbag made from apple leather by designer Luca Nichetto.

The photography is courtesy of Modern Synthesis.