Aluminum house by Atelier Tekuto

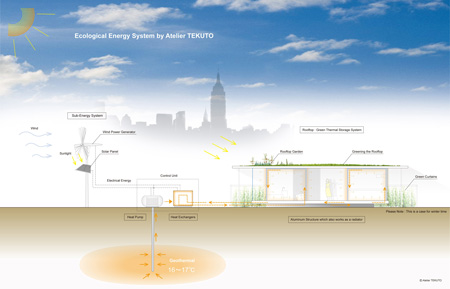

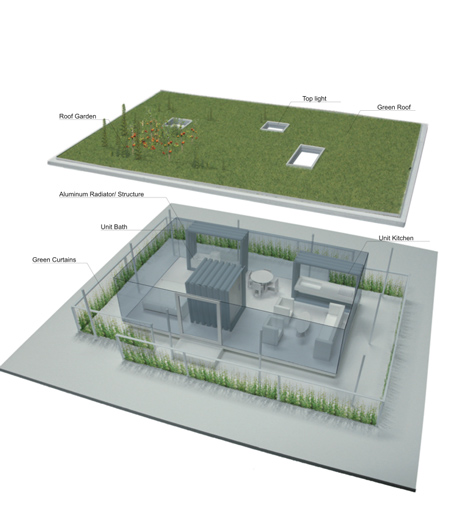

Tokyo architects Atelier Tekuto have developed a prefabricated aluminium house with walls that act as both structure and thermal radiators.

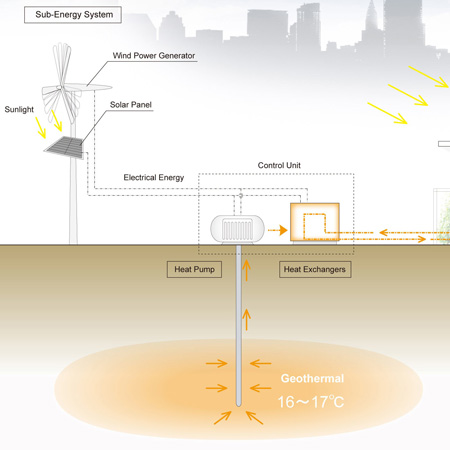

The house makes use of geothermal heat, which is pumped through the aluminium structure.

The heat exchange system is powered by a wind turbine and photovoltaics.

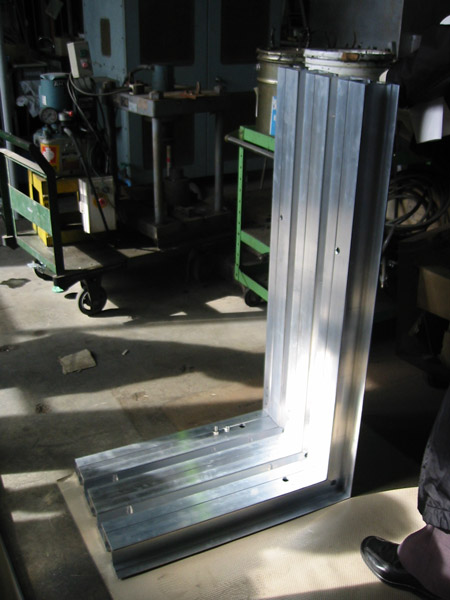

The aluminium components are currently being fabricated in a factory.

The hollow construction of the components allows hot and cold water pipes and electrical cables to be channeled through the walls.

A small room was built to test the system and the house is due to be constructed later in 2008.

Here is some more information from Atelier Tekuto:

--

Aluminum Project

Prefabrication System Using Aluminum as a structure and a thermal radiator device (heat control system)

In 1997, Kyoto Protocol to the United Nations Framework Convention on Climate Change has passed. Most industrialized nations agreed to legally binding reductions in greenhouse gas emissions to certain levels in order to prevent dangerous anthropogenic interference with the climate system.

In Japan, the revised building standard law approved use of aluminum as structure in 2002. Although the manufacture of aluminum requires enormous amounts of electricity when being manufactured, the quality of metal stays stable and it's perfect for practicing the ‘3R’s’: Reduce, Reuse, Recycle. Recycling aluminum requires only 3% of the energy to produce it. Changing the great amount of architectural waste into aluminum and recycling it results in reduction of environmental damage in a long run.

Aluminum is also low weight and high strength. Moreover, it's easy to manufacture during plasticity processing and enables us to create flexible sections. This is why using aluminum as a construction material provides high efficiency not only in manufacturing and designing details and texture, but in unifying them with structure and finishing.

This remarkable feature of aluminum led us to start the Aluminum Project in the northern part of Japan called Kanazawa (Ishikawa prefecture), famous for cloudy sky, heavy snowfall, high humidity, and one of the major industrial districts for manufacturing aluminum. It is our task to provide a comfortable residential environment for those who live in this severe northern climate under the five principles of the aluminum project. The joint project has been carried out with about 10 university-industry-government collaborators.

We propose this project as an attempt to introduce an aluminum structure which also works as a thermal radiator device and reduces the running costs zero, using natural resources. For thousands of years, we have been building architecture with passive thinking in Japan. Now is the time to consider again from the beginning and let the world know how we could create architecture with a mutual prosperity with nature, while applying new technologies so that architecture could raise global awareness of environmental issues. We propose this project as one of the ways to approach ecology, which we believe will play a significant role in the future potential of prefabricated architectures.

The Five Principles of Aluminum Project.

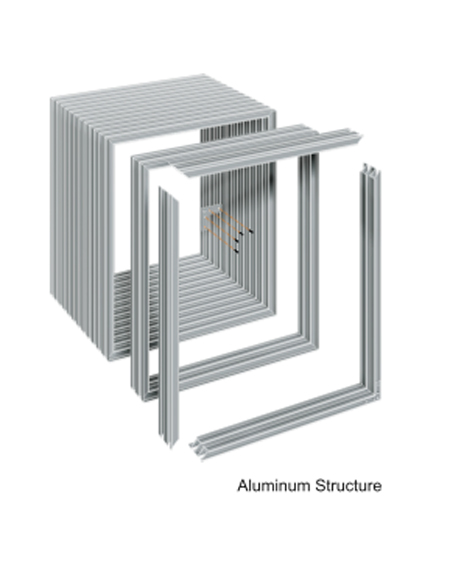

1. aluminum structure

Having done many studies on the aspects of unit strength, economy, execution of work, we came to a transformed deck plate which makes columns, walls, beams and slabs with one simple mould. This ring-like structure, consisting of the extruded aluminum, becomes a basic structure of the aluminum house. The joint is fairly easy to assemble for most carpenters and engineering builders.

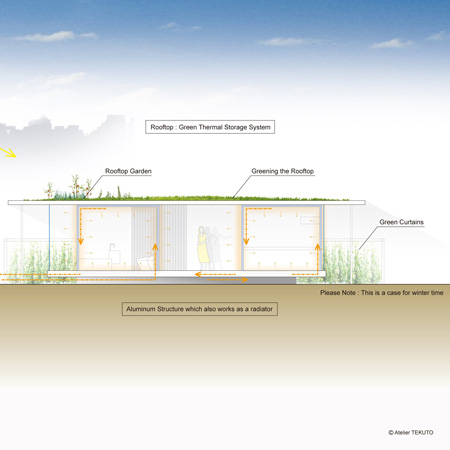

2. alumimum structure, isolated from the external environment

The thermal conductivity of aluminum is about three times higher than that of steel and it's likely to stimulate condensation and heat loss. Usually this occurs when aluminum is exposed to the severe gap between outside/inside temperature, meaning that if we could isolate the aluminum structure from the outside air this problem can be solved.

3. aluminum structure as a thermal radiator device

Following the rules listed above results in better thermal conductivity and better thermal radiation and reflection conditions. Pipes inside the hollowed-out aluminum molds allow hot water or cold water to circulate within the ring-formed structure.

4. keeping the original texture of aluminum

Aluminum has a dull glow and allows a rich silvery look when not anodic oxide coated and has a decent thickness. This distinguished feel as a material can not be achieved with other materials such as wood, steel, nor concrete.

5. structure functioning as an equipment space

The hollowed-out aluminum moulds not only work as a radiator which circulate hot and cold water but also as a pipe for the electric equipment system. After the construction of the pipe arrangement and track layout, removable aluminum flat bars get installed allowing continuous aluminum surfaces to appear and making it easy to maintain.

Aluminum Project Mock-up in KANAZAWA

In the courtyard of governmental office building of Nonoichi-city, we made a temporary space about a size of an eight-mat room and installed aluminum rings 2.1m×2.1m×2.1m.

Thermal Radiation Device Experiment

The biggest reason for building a mock-up was to physically experience the thermal radiation. In fact it was important to actually test the aluminum-made thermal radiation device and see if most people would accept the idea. During the two weeks we had exhibited the aluminum-made rings in a space about a size of an eight-mat room, about 200 people visited and physically experienced the device and they liked it very much. This time we activated the device as a heater because it was in winter and obtained a good result with radiated heat, performing the slow rise in temperature inside the room, and stability of temperature with aluminum surfaces.