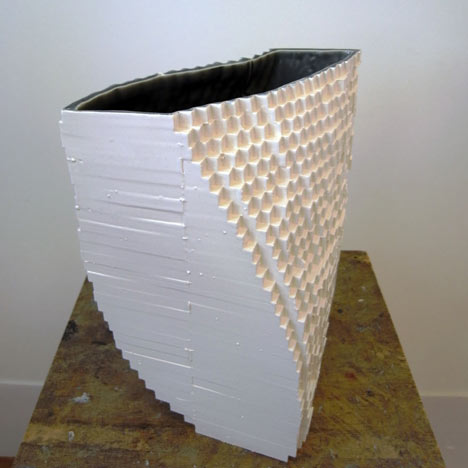

Pixel Mould by Julian Bond

Design graduate Julian Bond of the Royal College of Art has created a moulding machine to produce vases, each with its own unique design.

Called Pixel Mould, the machine produces vessels using a single mould made up of over 1300 individual plaster sticks.

The sticks can be individually reconfigured to create unique moulds.

Clay is poured into the mould, fired and glazed to create the final product.

The vases are created using a traditional slip casting technique, which usually uses fixed moulds, however this machine allows users to create their own one-off designs.

See a selection of this year's graduate work in our special category.

Here's a bit of text from the designer:

Pixel casting machine 2, 2010.

Pixel vases are produced using a mould that is made up of over 1300 individual plaster sticks, which are moved individually to form unique moulds, unlike a normal slip casting mould which is fixed.

Once the user is happy with the design, clay slip is poured into the mould to create the final object.

The clay is then fired and glazed. The objects can take many forms but are all related due to the technique that is used to produce them.

This project was about giving anyone the ability to engage with the slip casting technique and allowing them to create a one off design.

The machine is designed to engage with the user allowing them to understand the form they are creating.

This is a rapid manufacturing tool, not rapid prototyping, each piece that is made can be used as a final product.

See also:

.

|

|

|

| Caged Message vases by Alexis Themistocleous |

Cardboard Cloud by Fantastic Norway |

More design stories on Dezeen |