Building Bytes 3D printed bricks by Brian Peters

Dutch Design Week: architect Brian Peters has adapted a desktop 3D printer to produce ceramic bricks for building architectural structures (+ movie).

"I've been working with desktop 3D printers for the past couple of years and wanted to transform the machine to build something on a larger, more architectural scale," Peters told Dezeen.

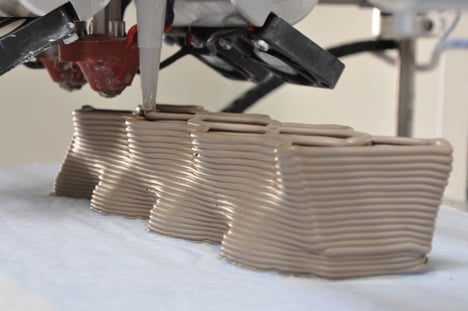

A 6-week residency at the European Ceramic Work Centre in the south of the Netherlands provided him with the opportunity to experiment with printing ceramics from a liquid earthenware recipe normally used in mould-making.

The only modification required for the printer was the addition of a custom extrusion head.

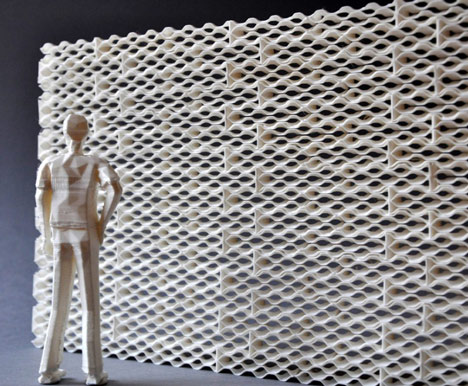

The resulting Building Bytes project predicts that 3D printers will become portable, inexpensive brick factories for large-scale construction.

"You could have several of these machines working simultaneously on site using pre-made or locally manufactured material," he says. "It doesn't have to be necessarily ceramic - it could be concrete or cement or any mixture of building materials."

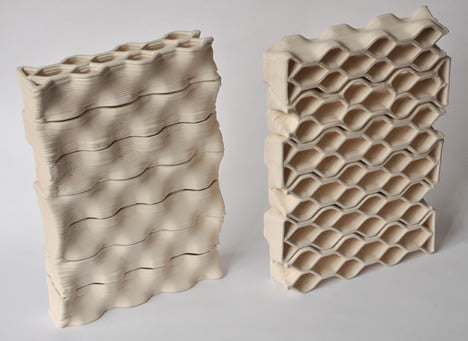

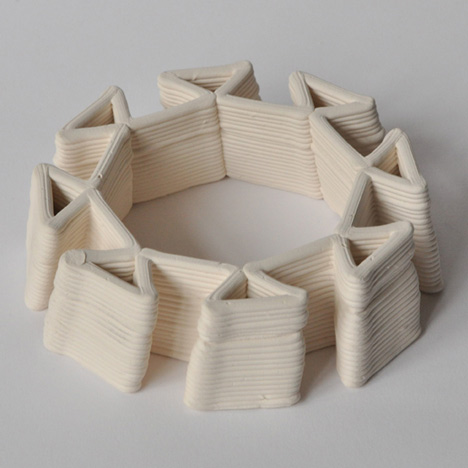

Peters developed two approaches to construction using the bricks: a uniform structure using multiples of the same brick, or a varied structure where each brick is uniquely shaped to create a complex form.

"It takes 15 minutes to print a brick at the moment so I don't think I'd be necessarily competing with existing construction materials but the benefits are that you can design a custom-made house or structure and have it assembled on site," he said.

For Dutch Design Week Peters demonstrated the machine and showed some of the brick patterns he's developed at Schellensfabriek, a former textile factory in Eindhoven, as part of the Show Your Color exhibition presenting work from artists' residencies with Dutch organisations including the European Ceramic Work Centre.

Based in Amsterdam, Peters is co-founder of architecture studio Design Lab Workshop and is currently working with DUS Architects to create a large 3D printer for making full-scale structures.

3D printing is a hot topic at the moment and other applications of the technology for construction include a house that would be 3D printed in sections then fitted together on site and a robot that creates architectural structures from sand or soil. See all our stories about 3D printing.

Dutch Design Week took place from 20 to 28 October and you can see all our stories about it here.