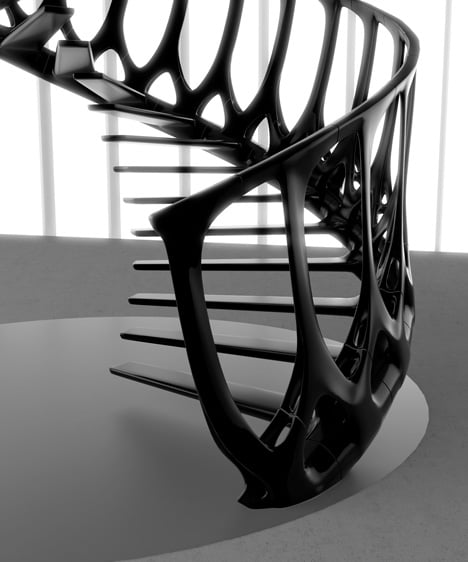

Vertebrae Staircase by Andrew McConnell

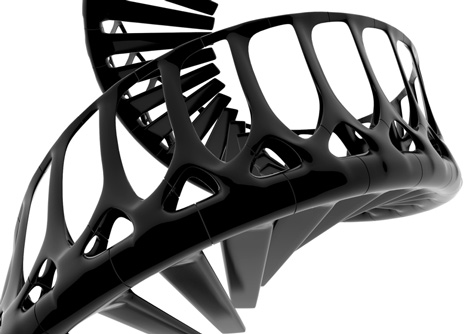

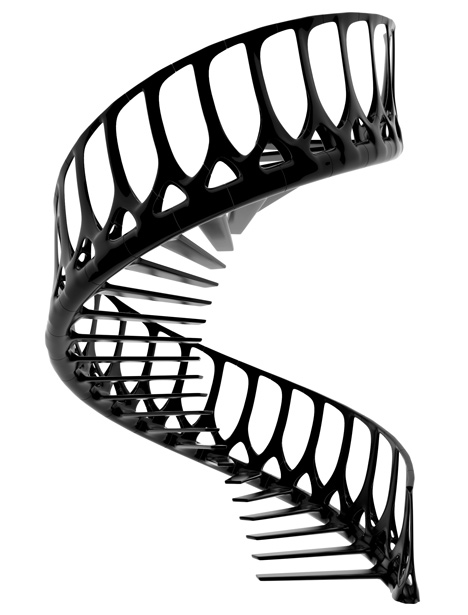

This staircase concept by Canadian architect Andrew McConnell is based on a whale's backbone (+ slideshow).

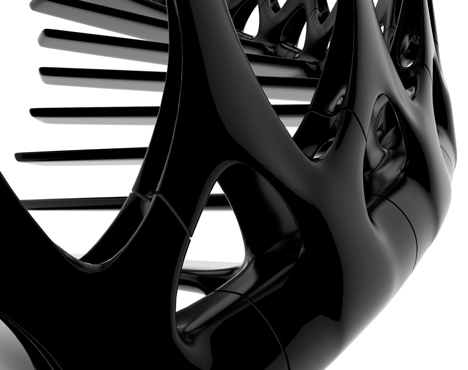

Andrew McConnell came up with the Vertebrae Staircase concept by simplifying the shape of a whale's vertebra into a single component.

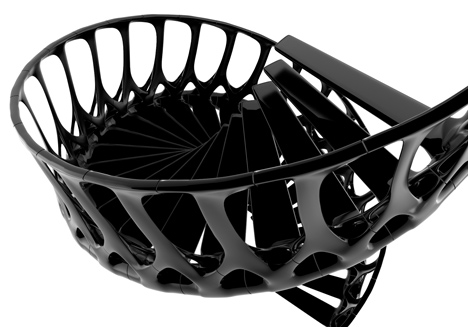

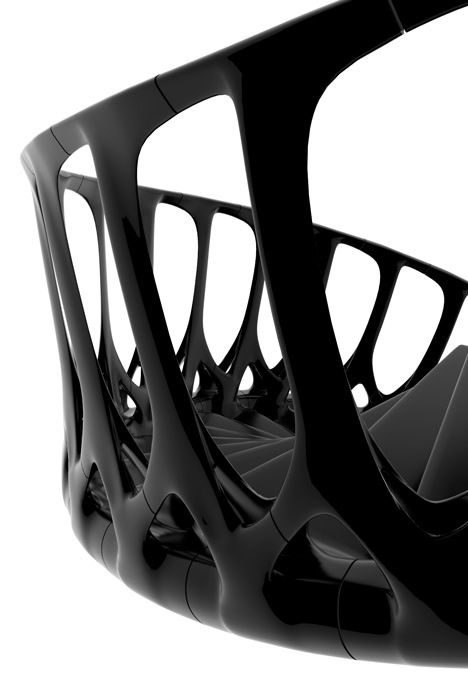

Each piece would incorporate one step, one banister and part of the hand rail, interlocking to create a rigid, self-supporting structure.

Two slightly modified components would be used to connect the floor plates, while metal fittings would mate one element to another.

"One benefit of this design is that its fabrication would require the production of essentially only one element repeated several times," McConnell told Dezeen.

"There are no other hidden supports as the Vertebrae Staircase is designed to act as one structural element, bearing the loads of its users and transferring these forces to the floor plates.

McConnell completed his Master of Architecture in Calgary, Canada, before starting work as an architect in Rotterdam, the Netherlands.

We've featured dozens of unusual staircases on Dezeen, including one built into a kitchen counter and another that looks like a slice of Swiss cheese – see all our stories about staircases.

We've also published objects made of bones collected from an abattoir and a range of handles and hooks shaped like sticks and bones.

See all our stories about staircases »

Here's some more information from the designer:

Inspired by the spine of a whale, the Vertebrae Staircase is not simply mimicry of organic form but an exploration in shaping structure. Much of the design work went into refining the single component, or vertebra, that mate with each other creating a unified spine running from floor plate to floor plate. These interlocking vertebrae provide a rigid structure for the steps, railing and its users. And the railing is reinforced by connections that help the staircase resist rotational forces caused by the cantilevered steps.

The Vertebrae Staircase is a reconfiguration of a familiar form and its connections, resulting in a unique yet functional piece of vertical circulation.