How we 3D-printed our heads

Rather than publish our photos on the contributors' page of the Print Shift 3D-printing magazine we launched this week, we thought it would be fun to get ourselves scanned and printed out. Here's how we did it.

First we headed to Sample and Hold, a scanning bureau in Dalston, east London, down the road from the Dezeen office. Sample and Hold has developed its own scanning system featuring 18 professional DSLR cameras mounted in a semicircular grid.

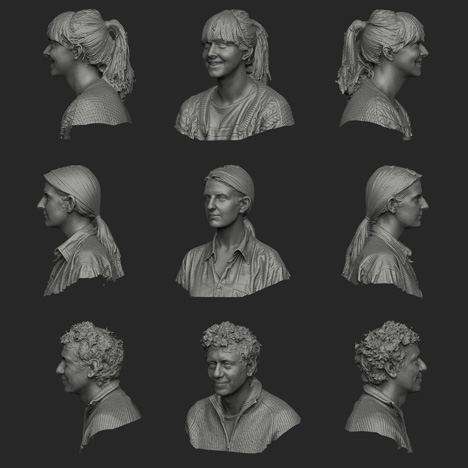

We took turns to sit motionless in the centre of the array as the cameras captured us from multiple angles. Sample and Hold then merged the images to build up a 3D likeness of each of our faces.

This system has an advantage over other scanning techniques because it is near-instantaneous and so can capture natural facial expressions.

However, it is not so good at dealing with the complexity, volume and low tonal range of the average hairstyle, so a Mephisto scanner was used to scan the back and sides of our heads.

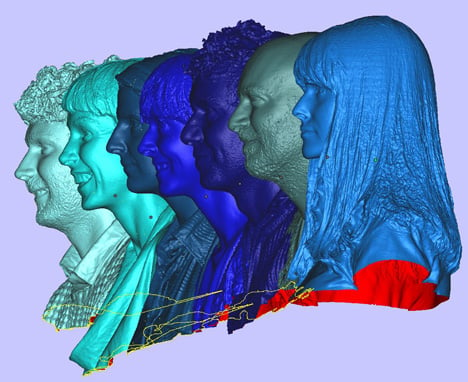

This device projected a pixellated pattern onto the hair and recorded the position of each pixel to create a digital model of the hairdo. Sample and Hold merged this with the facial scans to create the final 3D model of each person.

We then took the 3D files to creative 3D-technology company Inition in Shoreditch, east London, to be printed. Further processing was required to make the files print-ready: the 3D models were hollowed out and scaled to the appropriate size and then broken down into a sequence of two dimensional layers to be printed.

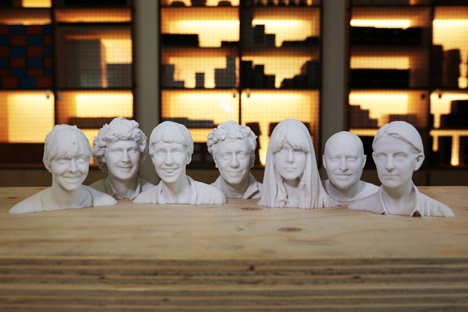

Inition printed our heads with a ZPrinter, which fuses layers of plaster powder with a binding agent. All seven of our heads were printed together, which took eight hours. Any unbound powder was then vacuumed and brushed away, revealing the fully-formed 3D models inside.

Unboxing the heads at the Dezeen office was an uncanny experience, as it was the first time any of us had seen a three-dimensional likeness of ourselves. “I wish I’d brushed my fringe,” said Rose while Paul’s reaction was: “Who’s the bald guy?”

Sample and Hold used the same processes to scan a horse for the Turner prize-winning artist Mark Wallinger, who used the resulting 3D model to create a life-sized marble and resin statue.

We also previously featured Inition's augmented-reality iPad app that allows architects to look inside static architectural models, visualise how their building will look at night and track how wind flows around their design proposals.