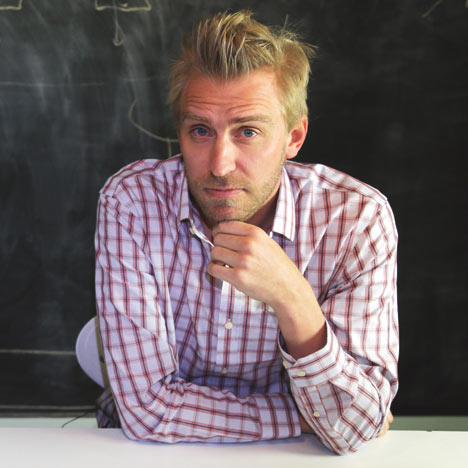

"Everyone will be interested in making things instead of buying things" - Janne Kyttanen

Freedom of Creation co-founder and 3D Systems creative director Janne Kyttanen tells Dezeen that he believes one day everyone will have easy access to 3D printing in the first of our series of video interviews with pioneering figures in the world of additive manufacturing. Update: this interview is featured in Dezeen Book of Interviews, which is on sale now for £12.

We visited Kyttanen during a road trip across the Netherlands and Belgium, where many of the major players in 3D printing are clustered, as part of our research for Print Shift, the one-off magazine about 3D printing that we launched earlier this year.

In the movie, Kyttanen says that the actual technology behind additive manufacturing hasn't changed much in recent years, but the interest in it has rocketed.

"When it comes down to the technologies themselves, fundamentally nothing has changed," he says.

"The biggest change that has happened is the awareness. People know that these things exist; they know the possibilities. Also, the ease of use of software: pretty much everything is getting easier and easier and once that happens the masses start picking it up."

In 2011, Kyttanen's design studio Freedom of Creation, which pioneered the use of 3D printing technology to create consumer products, was acquired by American 3D printer manufacturer 3D Systems and he now acts as creative director for the company.

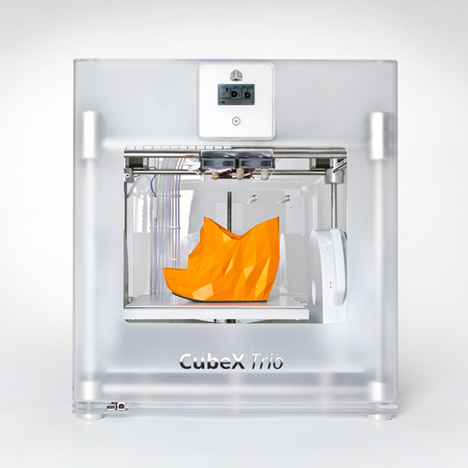

Having been at the forefront of 3D printing since the 1980s when the company's founder Chuck Hull invented stereolithography (SLA), 3D Systems has recently turned its attention to the consumer market. In 2012 it launched the Cube, an affordable desktop 3D printer promising the kind of plug-and-play simplicity we have come to expect from the electronic products in our home.

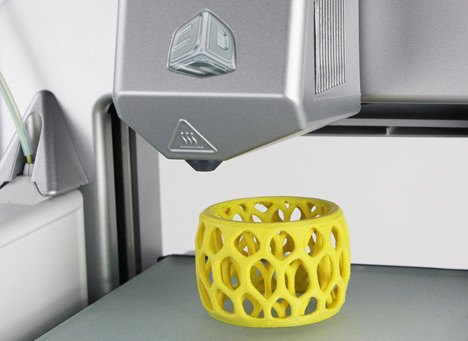

"We want to put 3D printing in every home," says Kyttanen. "A lot of the home machines that came on the market were open-source and people could tinker with them. What we're trying to do is to make products where you can just open the box, take out the machine, plug it in, send a file and it starts printing. That's truly what's happening with the Cube."

The machine became the first domestic 3D printer to be sold on the shop floor by a US retailer when Staples announced plans to stock it in May.

The Cube is a simple fused-deposition modelling (FDM) machine, which builds up objects layer-by-layer using a plastic filament fed into a heated print nozzle. "The Cube is the most plug-and-play 3D printer on the market at the moment," Kyttanen claims.

Recently, Kyttanen launched a range of women's shoes that can be printed out overnight on the larger version of the printer, the CubeX. He strongly believes that as the technology moves into people's homes, it will transform the way they act as consumers.

"Everyone will get interested in design and making things instead of just being consumers and buying things," he says. "The designer's role [will be] merely creating better templates for all these people."

He continues: "If you want to customise something for yourself, now you have the ability to do that. You can make any shape you want. Now everybody has the power to do whatever they want, with very easy tools."

It is this ability to customise products, Kyttanen says, which will drive the demand for 3D printing in the home.

"People always ask me what would be the killer product for the technology, what would sell the most," he says. "I always tell people that I don't think it's a product at all, I think it's the empowerment itself."

See all our stories about 3D printing »

See all our stories about Janne Kyttanen »

Find more information about Print Shift and see additional content here.