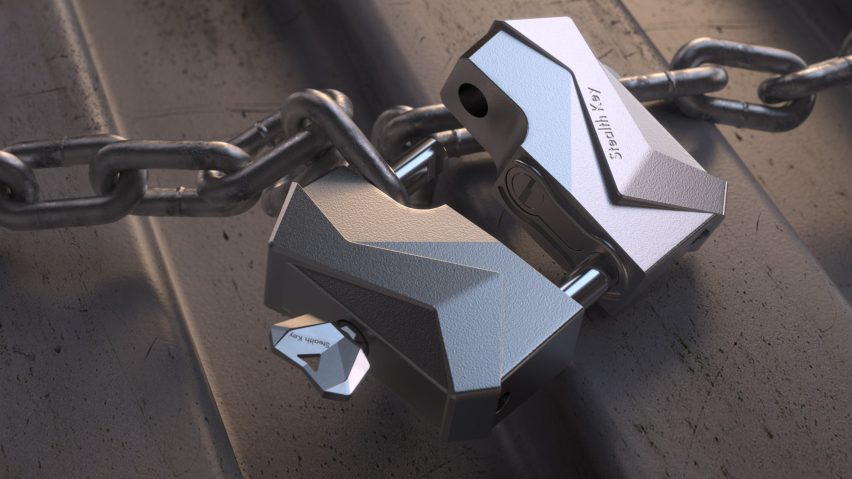

UrbanAlps' 3D-printed Stealth Key is almost impossible to forge

Swiss company UrbanAlps has devised a method for 3D-printing keys to make them almost unforgeable, because their teeth are hidden from view.

The Stealth Key was designed by UrbanAlps as a safer alternative to regular keys, which can be easily scanned and copied.

In what the company says is a world first, the keys are 3D-printed from titanium. Because they use a form of additive manufacturing, the keys are effectively formed from the inside out – meaning their teeth can be hidden under a pair of narrow ledges.

However, they work like most contemporary keys, fitting inside a cylinder lock to turn the mechanism.

While the company's founder Alejandro Ojeda doesn't claim the key is totally unforgeable, he says it will "raise the bar of difficulty" for copiers.

"We do not claim that the key is impossible to copy, but that the masses cannot," he told Dezeen. "MacGyvers with special tools can certainly accomplish it. With the Stealth Key, we raise again the bar of difficulty."

The Stealth Key is the result of a two-year research project undertaken by the company, during which they aimed to bring an affordable yet ultra-secure key to the mass markets.

"During the last two years we have pushed hard to develop the first of its kind security system," said the company. "We have developed a range of cylinder locks and un-scannable keys based on the Stealth Key concept."

"No matter how many pictures or home 3D scanners are used, it cannot be copied: the simplest and affordable key copy protection."

Currently, the process allows up to 850 keys to be made in 24 hours and is compatible with both Swiss and European cylinder lock profiles.

While 3D printers have not yet become common in households, the technology is proving a fertile ground for researchers. At the Massachusetts Institute of Technology, researchers have developed a method for 3D printing artificial hair, while at the Bartlett School of Architecture, students have 3D-printed concrete to create furniture.

Other structures that have been 3D printed range from homes to bicycles, wheelchairs and shoes.