Self-healing "e-skin" could provide amputees with realistic sensations

Scientists believe that a newly developed electronic skin that is able to mimic the function and properties of human skin could help to create prosthetics capable of providing sensory feedback.

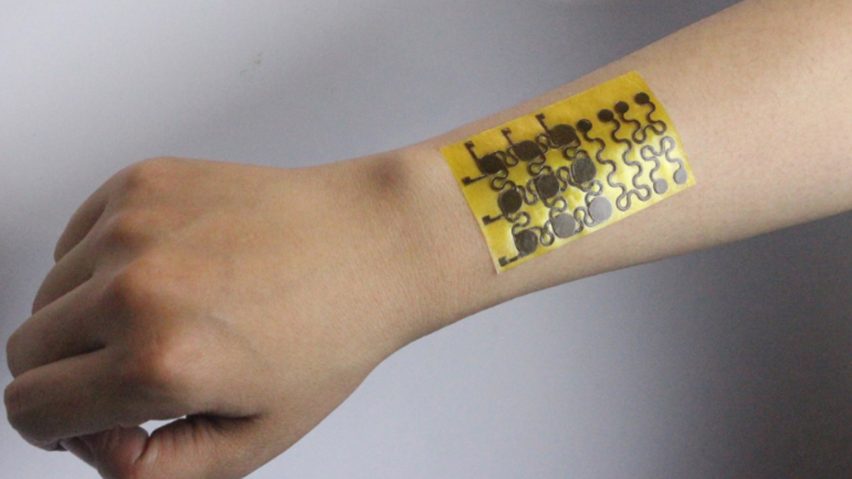

Developed by University of Colorado Boulder scientists, the so-called e-skin is a thin, semi-transparent material that is able to repair itself.

As it is malleable, the material is able to easily wrap around complex, curved surfaces, and – just like human skin – it can sense pressure and differs in temperature.

E-skin could be used in prosthetics

The scientists behind the material believe that its unique properties make it suitable for a broad range of applications in robotics, prosthetics and health care.

"The e-skin is robust yet flexible and malleable and thus can find applications in robotics, prosthetics, and biomedical devices," said the team in its study, which was published in trade journal Science Advances earlier this week.

"In prosthetics, it could be used on a bionic hand to sense for pressure when holding a glass cup and prevent the user from accidentally crushing it, or prevent burning if the contents is hot."

Material could allow robots to experience human sensations

The team also envisage it being used to enable robots to read a person's temperature or detect a fever by a single touch.

"Let's say you wanted a robot to take care of a baby,” said Jianliang Xiao, an assistant professor in at the university's Department of Mechanical Engineering who is leading the research effort.

"In that case, you would integrate e-skin on the robot fingers that can feel the pressure of the baby. The idea is to try and mimic biological skin with e-skin that has desired functions."

The e-skin is made from a polymer network named polyimine, which has been combined with silver nanoparticles that provide it with both strength and electrical conductivity.

Its surface is embedded with a number of sensors to measure pressure, temperature, humidity and air flow.

According to the Xiao, this material make-up allows the e-skin to be completely recycled. It also makes the material able to repair itself.

"What is unique here is that the chemical bonding of polyimine we use allows the e-skin to be both self-healing and fully recyclable at room temperature," said Xiao.

"Given the millions of tons of electronic waste generated worldwide every year, the recyclability of our e-skin makes good economic and environmental sense."

To recycle the skin, the material is soaked in a solution that degrades polymers down and separates the nanoparticles into oligomers and monomers – small molecules – that are soluble in ethanol.

The recycled solution and nanoparticles can then be used to make a new, functional e-skin.

The innovation follows on from other "bio-skin" developments such as a fabric developed by teams from MIT Media Lab and the Royal College of Art that peels back in reaction to sweat and humidity.

More recently MIT researchers created a transparent film that stores solar energy and releases it on demand, as well as a material that expands and contracts when exposed to different temperatures.