Recycled plastic turned into face shields and hands-free door handles to fight coronavirus

Recycling initiative Precious Plastic's open-source machines are being used to recycle plastic and turn it into face shields, respirator masks and hands-free door handles to fight coronavirus.

Designers and makers that use the Precious Plastic machines are repurposing them to make items needed by local health care workers.

Groups in Germany, Spain, Greece, Austria and Switzerland are using the open-source machines, which shred and remould old plastic, to make face shields, masks for ventilators and handles that allow the user to open a door without touching it.

Precious Plastic La Safor and Precious Plastic Gran Canaria have been making and sharing designs for visors that sit on the forehead and hold plastic shields over the wearer's face.

"A Precious Plastic workspace in Gran Canaria was requested to provide over 3,000 face visors for the government, hospitals and private sector," said Precious Plastics member Rory Dickens.

Their injection moulding machines can manufacture personal protective equipment (PPE) 75 times faster than a 3D printer explained Dickens, who co-founded UK nonprofit Recycle Rebuild.

In Germany, the Kunststoffschmiede plastic recycling workshop is using its machines to make 20,000 visors for the Dresden area. Plasticpreneur in Austria, which makes machines for the project, has also gone into mass production.

These face shields protect the wearer from infectious droplets spattering on them and help keep their face masks dry. Medical-grade N95 or FFP2 masks must be replaced if they get wet, but are in short supply all over the world.

The Gran Canaria workshop is also prototyping face masks for ventilator machines for use in intensive care units.

"No official body has approved our designs for medical use at this time, however, several hospitals around the world – including those in Spain – are currently using them," said Dickens.

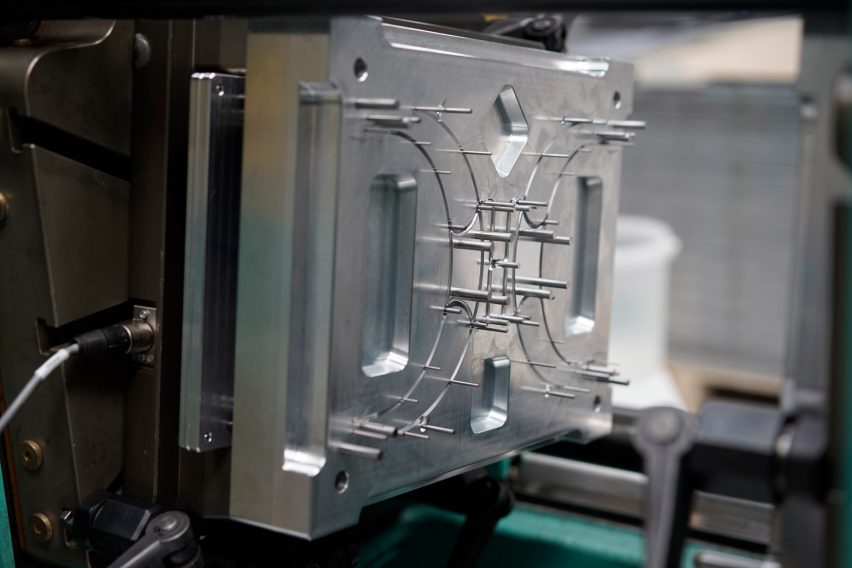

Greek company Alumoulds, which make moulds for Precious Plastic machines, is working with Precious Plastic Leman in Switzerland to make hands-free door handles.

The coronavirus can live on surfaces for days, and people can catch it by touching a door handle and then touching their mouth or eyes. Opening doors without hands helps prevent the spread of infection.

According to Dickens, thePrecious Plastic workspaces are being very careful about hygiene when making the PPE.

"To make the items the plastic is heated to over 200 degrees Celsius which sterilises the plastic and it has previously been cleaned," he explained.

"The workspaces follow strict guidelines on how to maintain a clean working environment suitable for making the masks and storing them to avoid contamination," he added.

"The injected items also benefit from not being porous like 3D printed counterparts, ensuring bacteria and viruses can't hide inside the plastic."

Hospitals treating coronavirus patients need this emergency PPE to keep their staff safe, as medical workers are particularly vulnerable to being seriously infected.

Infection control guidelines mean PPE must be disposed of after use, Dickens said Precious Plastic could offer a way to recycle any discarded plastic.

"Covid-19 has been proven to last up to nine days on the surface of plastic items," he said.

"However, as long as the items can be disinfected, I see no reason why they would need to be incinerated, and instead could be cleaned, shredded and recycled into one of Precious Plastics other opensource products."

Founded in 2014 by Dave Jakkens, Precious Plastic shares designs for its machines as open source, so anyone can design and build a recycling system.

Shredder machines take sorted plastic waste and turn it back into useable flakes of plastic. Separate machines, including an injection moulder, an extruder or a rotation moulder, turn the flakes back into useful objects.

Other design teams responding to the PPE shortage include MIT in the US, where researchers have invented a flat-pack face shield that can be assembled from a single piece of plastic.

In China, 3D printer company Creality 3D has designed and donated thousands of buckles that hold a face mask in place without hurting the wearer's ears.

Images are courtesy of Precious Plastic.