Making protein from CO2 can "remove the climate impact of food" says Solar Foods CEO

Food made from captured atmospheric carbon could feed the world while helping to combat climate change, according to Solar Foods CEO Pasi Vainikka.

"We can capture CO2 anywhere," said Vainikka, whose company has developed a protein powder made using carbon dioxide.

"That is a strategic shift where you don't really need arable land and your raw materials are in the air."

The vegan protein powder, called Solein, is created by microbes that metabolise carbon dioxide, absorbing the carbon so they can grow while releasing the oxygen.

The powder can be turned into meat and dairy substitutes or added to foods and shakes as a nutritional supplement.

Solar Foods claims that Solein eliminates most of the emissions associated with modern agriculture, which is responsible for almost one-third of all greenhouse gas emissions.

One kilogram of Solein emits 0.2 kilograms of carbon dioxide equivalent (CO2e) in its production, Solar Food claims. In comparison, beef herds produce around 100 kilograms and chicken 10 kilograms of CO2e.

Solein could "remove the climate impact of food systems"

"[We can] remove the climate impact of food systems on the planet, which today account for about 30 per cent of global greenhouse gas emissions," Vainikka said. "That can happen if we replace meat and dairy at a large scale."

The company's factories also require a fraction of the land used for industrial farming, potentially freeing the land up for reforestation. This means Solar Foods could indirectly help tackle climate change, it claims.

"We could free up agricultural land to grow back forests," Vainikka said. "Those remove carbon permanently from the atmosphere."

On its own, turning atmospheric carbon into food does not tackle climate change since once consumed, the carbon soon enters the atmosphere again via the natural carbon cycle.

"Solein does not reduce the concentration of carbon dioxide in the atmosphere directly, but the indirect effect is that we need about one-tenth of the land compared to photosynthesis," Vainikka said.

"It's not really carbon storage because 95 per cent of the carbon we eat comes out as breath and the remaining 5 per cent from the other end."

Founded in 2017, the Finnish company has so far created 20 different products from Solein at its pilot plant near Helsinki, which can generate a kilogram of food a day.

Thirty per cent of CO2 will come from the air

Later this year, Solar Food is set to start construction on its first commercial-scale plant, with the aim of producing five million meals a year and bringing the first products to market by 2030.

The brand claims the plant will be the "world's first commercial factory producing food out of air-captured CO2".

On-site direct air capture (DAC) units will suck CO2 from the atmosphere for use in the plant. "We will scale in steps, the first phase target is to have some 30 per cent of the CO2 come from the air," Vainikka said.

The remainder of the carbon dioxide will come from emissions captured from factories.

Scrubbing CO2 from factory chimneys does not remove carbon from the atmosphere but merely reduces the amount of new carbon being emitted.

But captured emissions are increasingly being used to produce products including the ethanol used in Air Co vodka and the CO2 bubbles in Valser's sparkling water.

To turn CO2 into edible protein, Solar Foods uses microbes that feed on it to grow and reproduce.

The microbes are similar to those that have played a longstanding role in the production of wine, bread and yoghurt but take hours rather than months to produce a result.

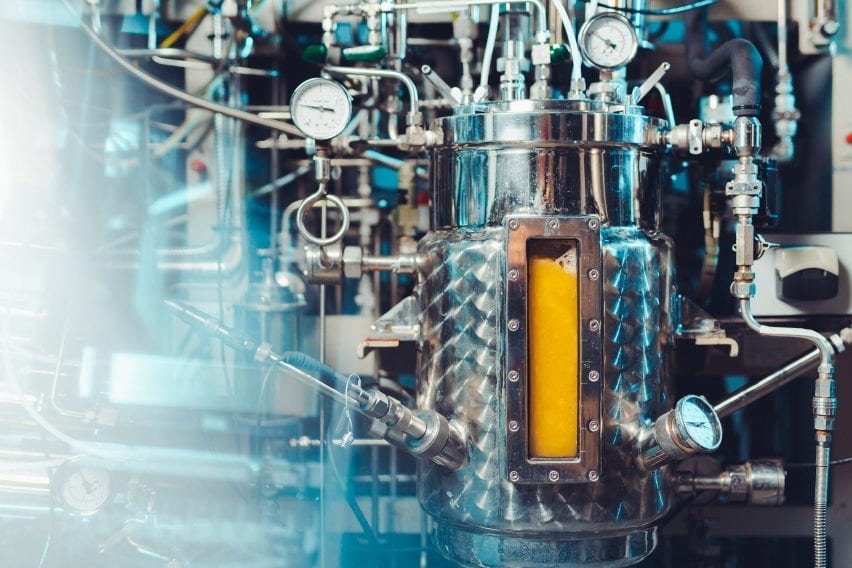

"It's similar to winemaking in the sense that we have a fermenter, a bioreactor, where we have our microbes, billions of them," said Vainikka.

Solar Foods' air-capture plans are based on technology developed by NASA in the 1960s to feed astronauts on lengthy space missions.

An air capture device sucks in carbon dioxide while water is split into hydrogen and oxygen via electrolysis. The three gases are funnelled into the bioreactor, along with a growth medium containing necessary minerals such as ammonia to feed the microbes.

Harvested and dried, that microbial slush becomes Solein – a yellow powder made up of single-cell protein, with a nutrient composition similar to dried soy or algae, and a flavour and texture similar to wheat flour.

Canadian company Kiverdi uses a similar process to make its Air Protein, as well as an ethical substitute for palm oil, an environmentally damaging ingredient that features in about half of packaged supermarket products.

"The key question Solar Foods is dealing with is, how do you enable a carbon-dependent society to shift to a circular carbon system?" Vainikka said.

"That's our perspective. It's about enabling the end of the concept of mining [fossil fuels]. It is practising an atmospheric circular economy."

Carbon revolution

This article is part of Dezeen's carbon revolution series, which explores how this miracle material could be removed from the atmosphere and put to use on earth. Read all the content at: www.dezeen.com/carbon.

The sky photograph used in the carbon revolution graphic is by Taylor van Riper via Unsplash.