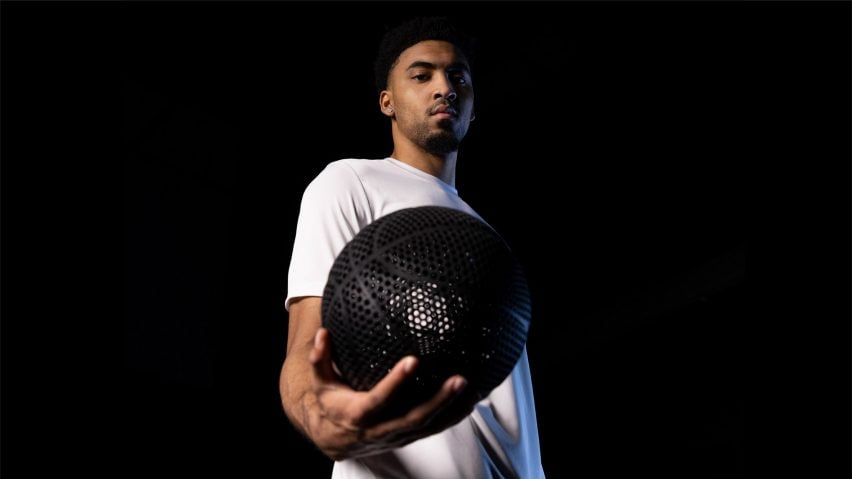

Wilson "reinvents the basketball" with airless 3D-printed lattice design

Sports equipment manufacturer Wilson has unveiled a prototype 3D-printed airless basketball that, unlike traditional balls, does not need to be inflated.

Made from an elastomeric polymer developed by Wilson, the airless ball has a see-through lattice structure with hexagonal holes that allow air to pass through it.

Although printed as one solid piece, the design features "seams" and eight panels that reference the design of traditional basketballs.

According to Nadine Lippa, Wilson's lead engineer on the project, the company aimed to develop a ball that performs the same as typical basketballs in size, weight and bounce but does not have to be inflated.

"My boss, Kevin Krysiak, originally charged me with reinventing the basketball," Lippa told Dezeen.

"One of the parameters or attributes that we felt could be improved upon is the fact that all inflatable balls eventually go flat, so the impetus for this was creating an airless ball that doesn't require the use of an air pump or a needle – it's just a single piece of equipment that you can just go out and play."

The most challenging aspect was making sure the ball bounced like other basketballs

Wilson collaborated with manufacturing company EOS to produce the ball, which was made using the selective laser sintering (SLS) method of additive manufacturing.

The method involved using lasers to fuse layers of polymer powder into the 3D design, which was then removed from the surrounding excess powder, sealed and dyed black.

"I think with a lot of 3D printing you can make a sphere but to make something that looks and feels like a basketball really just requires the next level," said Lippa.

According to Lippa, the most challenging aspect of developing the airless ball was ensuring it bounced similarly to other basketballs.

"One of the biggest challenges of the project was finding something that rebounds to the expected height that doesn't have air in, because the inflated ball really relies on its air pressure to generate rebound," Lippa explained.

"We put our 3D-printed ball through testing but we were still not quite satisfied with the durability aspect so we also hit the ball with a baseball bat," she continued.

"We were really pleased to see that we weren't able to really damage it, even in that aggressive of a condition."

By creating an airless ball, Wilson aimed to eliminate deflating issues caused by blunt force, manufacturing defects or air escaping through the valve over a long period of time.

The airless design also overcomes contraction in inflated balls caused by changing environments and temperatures.

"If you have the same amount of air inside an inflated ball and then you go in a cold environment, the contraction of the air causes the ball to appear or play like it's flat," Lippa explained.

The ball prototype was unveiled in February at this year's NBA All-Star Weekend, where members of the public were invited to play with it. Wilson is undertaking further research before officially releasing it as a product.

Other basketball-related designs that have been featured on Dezeen include Nike basketball trainers with self-lacing technology and a basketball-shaped bottle designed by Hennessy to mark NBA's 75th anniversary.

Images and videos courtesy of Wilson Sporting Goods Co.