As part of our review of 2023, Dezeen's design and environment editor Jennifer Hahn has rounded up 10 of this year's most significant material innovations, including bricks made from toxic soil and a 3D printer for wool.

Over the last 12 months, designers found new uses for bacteria, using the microorganisms to colour textiles, grow a leather alternative and turn plastic waste into vanilla ice cream.

In architecture, researchers continued to reinvent concrete, with some using algae instead of cement as a binder while others rediscovered the secret to "self-healing" Roman concrete.

Energy efficiency was an ongoing concern in light of the recent energy crisis, with projects such as water-filled windows and colour-changing cladding aiming to passively heat and cool buildings without relying on fossil fuels.

Read on for Dezeen's top 10 material innovations of 2023:

Water-Filled Glass by Matyas Gutai, Daniel Schinagl and Abolfazl Ganji Kheybari

One of Dezeen's best-read stories of the year looked at how researchers from Loughborough University combined two ubiquitous materials – water and glass – in a new and innovative way.

As the name suggests, their Water-Filled Glass windows consist of a thin layer of water wedged between two panes of glass, which can reduce a building's energy bills by around 25 per cent compared with standard glazing.

That's because the water absorbs warmth from sunlight and heat loss from the interior that can then be diverted to help heat the building, while also limiting solar heat gain in the warmer months.

Find out more about Water-Filled Glass ›

Colorifix by Orr Yarkoni and Jim Ajioka

Synthetic biologists Orr Yarkoni and Jim Ajioka have developed a way of colouring textiles using bacteria in place of toxic chemical dyes which is already being used by mega-retailer H&M and experimental clothing brand Vollebak (pictured above).

Their Colorifix technology uses bacteria that is genetically engineered to produce different colour-making enzymes, creating a dyestuff that is compatible with the textile industry's standard dye machines.

Crowned material innovation of the year at the 2023 Dezeen Awards, the technology offers a scalable alternative to chemical dyes while using 77 per cent less water and producing 31 per cent fewer carbon dioxide emissions, the company claims.

Find out more about Colorifix ›

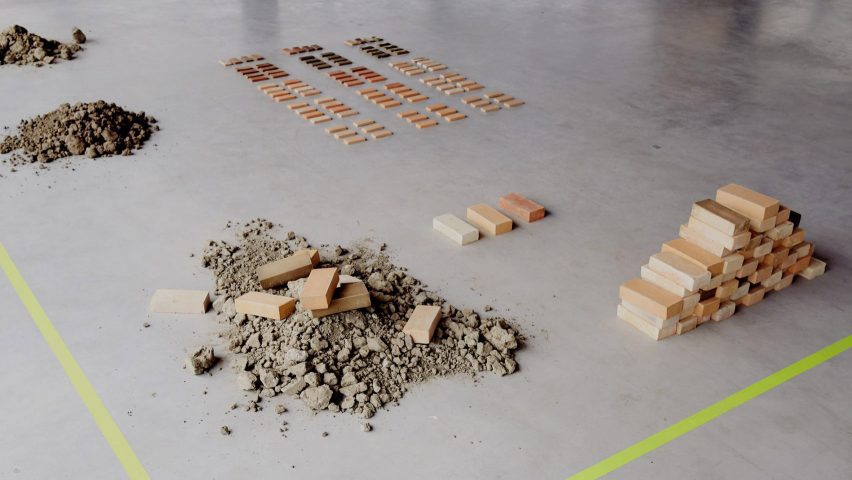

At Dutch Design Week, designer Emy Bensdorp presented a series of bricks made using clay contaminated with PFAS – toxic "forever chemicals" used for water- and fire-proofing, that can leak into our soils and waterways.

In the Netherlands, where PFAS can be traced in up to 90 per cent of soils, developers and landowners must now legally take responsibility for this contaminated soil, which ends up being hidden away and left to gather dust in depots with little prospect for the chemicals' removal.

Bensdorp discovered that firing the clay into bricks at high temperatures can eliminate these highly durable chemicals while turning the soil from a burden into a useful building material via an existing industrial process.

Find out more about Claybens ›

Guilty Flavours by Eleonora Ortolani and Joanna Sadler

Central Saint Martins graduate Eleonora Ortolani created a bowl of vanilla ice cream that she believes might the world's first food made from plastic waste.

The ice cream was made by taking a small amount of PET plastic waste and breaking it down using genetically engineered bacteria to create synthetic vanillin – the flavour molecule in vanilla.

Originally developed by researchers from the University of Edinburgh, the process produces a flavouring that is chemically identical to vanillin derived from crude oil, which is commonly sold in stores. The only difference is that it uses a recycled instead of a virgin fossil feedstock.

Find out more about Guilty Flavours ›

Electrochromic cladding by the Hsu Group

Researchers from the University of Chicago have developed a "chameleon-like" facade material that can change its infrared colour – the colour it appears under thermal imaging – based on the outside temperature to keep buildings cool in summer and warm in winter.

The composite material appears yellow under thermal imaging on a hot day because it emits heat and purple on cold days when it retains heat. This colour change is triggered by a small electrical impulse, which either deposits copper onto a thin film or strips it away.

"We've essentially figured out a low-energy way to treat a building like a person," said materials engineer Po-Chun Hsu. "You add a layer when you're cold and take off a layer when you're hot."

Find out more about this electrochromic cladding ›

Flocks Wobot by Christien Meindertsma

Dutch designer Christien Meindertsma has opened up new uses for the wool of European sheep, which is too coarse to form textiles and thus often discarded, by developing a custom robot arm that acts much like a 3D printer.

The Flocks Wobot connects layers of the material through felting to create three-dimensional shapes without the need for any kind of additional binder.

So far, Meindertsma has used the robot to produce a sofa – currently on display at the V&A – but in the future, she claims it could equally be used to create everything from insulation to acoustic products.

Find out more about Flocks Wobot ›

Dutch design studio Loop Loop has developed the "world's first plant-based aluminium dying process", using bio-based pigments instead of ones derived from petroleum.

The Local Colours project adapts the traditional process of anodising, which involves using an electric current to oxidise the metal, creating a porous surface that is able to absorb colour before being dipped into a water-based pigment solution.

So far, the studio has created four different solutions – a deep pink made using madder root, a bright gold produced with red onion and a warm purple and mustard yellow derived from different flowers.

Find out more about Local Colours ›

Bio-Blocks by Prometheus Materials and SOM

Colorado start-up Prometheus Materials has developed a "zero-carbon alternative" to concrete masonry blocks that is bound together using micro-algae instead of polluting Portland cement, which accounts for around eight per cent of global emissions.

The company is working with architecture studio SOM to explore applications for the material, with a dedicated installation at this year's Chicago Architecture Biennial taking the form of a giant spiral.

"This project demonstrates how product development, design, and construction can come together to address the climate crisis in a meaningful way," said Prometheus Materials president Loren Burnett.

Find out more about Bio-Blocks ›

Modern Synthesis by Jen Keane and Ben Reeve

Modern Synthesis has developed a plastic-free leather alternative that drapes much like cowhide but could generate up to 65 times less greenhouse-gas emissions than real leather, the British start-up estimates.

The material is made by bacteria that is grown on a framework of threads and fed with waste sugar from other industries, which is converted into a strong, lightweight material called nanocellulose.

Danish fashion brand Ganni has already used the material to create a version of its Bou Bag (pictured above) that was revealed at the London Design Festival and could be commercially available as soon as 2025.

Find out more about Modern Synthesis ›

Roman concrete by MIT and Harvard

This year, researchers from MIT and Harvard made headlines when they discovered the secret ingredient found in "self-healing" Roman concrete, which they are now aiming to bring to market.

The ancient recipe that has allowed structures such as the Pantheon (pictured above) to remain standing for millennia integrates quicklime instead of the slacked lime found in modern concrete, the scientists have posited.

As rainwater runs through the cracks that form in concrete over time and touches the quicklime clasts in the concrete, this creates a calcium-saturated solution that recrystallises to "heal" the fissures.

Find out more about Roman concrete ›

This article is part of Dezeen's roundup of the biggest and best news and projects in architecture, design, interior design and technology from 2023.