Emy Bensdorp takes on PFAS pollution by turning "toxic" soil into bricks

Designer Emy Bensdorp has found a way to clean PFAS "forever chemicals" from contaminated clay soil by firing it into bricks as part of a project showcased at Dutch Design Week.

The acronym PFAS refers to per- and polyfluoroalkyl substances – a large group of chemicals that have been widely used to make items such as non-stick pans, umbrellas and waterproof mascara but are now known to be toxic.

These "forever chemicals" do not break down in the environment when they leak into our soils and waterways. But with her start-up Claybens, Bensdorp has proved she can eliminate PFAS chemicals from contaminated clay soil by firing it into bricks.

She utilises a standard brick manufacturing process, where the ceramics are heated to between 900 and 1,200 degrees Celsius in a kiln, destroying the PFAS chemicals to the point where no trace amounts are detectable in the final product.

The Dutch designer does not believe the process emits any toxic fumes or particles, but the testing for that is still to go ahead.

"The most interesting thing about these chemicals is that they're actually great because they are water resistant, they're fireproof and they last for a long time," Bensdorp told Dezeen. "But now we know that they last forever, which is less great. And they bioaccumulate as well."

"This is actually one of the first ways to break them down, using heat," she added.

The designer first embarked on the work in 2020, a year after a Dutch Council of State ruling on preserving natural environments brought the country's building industry to a halt and led to the discovery that PFAS could be traced in up to 90 per cent of Dutch soils.

The problem is particularly bad in certain hotspots, where industrial activity, incorrect waste management or heavy use of firefighting foam have resulted in soils with extremely high levels of PFAS.

Developers and landowners are now required to take responsibility for contaminated soil so it won't leach into groundwater but according to Bensdorp, this has so far largely meant storing it in a depot, with little prospect for the chemicals' removal.

"It's a big problem, not only in the Netherlands but in all of Europe," said Bensdorp. "Legislation is coming in more and more because we're learning how toxic these chemicals are. But until now, there was no solution for the clay soil."

Bensdorp's process makes use of the extreme heat of kilns to activate a chemical reaction called defluorination, which breaks down the chains of fluorine atoms that make up PFAS.

She could theoretically make tableware, roof tiles or other ceramics using the contaminated soil but believes bricks offer the most promising solution due to the scale of production and the fact that no changes would be required to existing infrastructure or processes.

"The heat breaks the carbon-fluorine bond that's one of the hardest to break," Bensdorp said.

"The project is based on academic research. But there, they heat it for usually a very short amount of time at 1,000 or 1,400 degrees. In the brick manufacturing process, you heat it at a similar temperature for a long time."

"That's why it's so great," she added. "We can actually fit it into the existing process and use its existing infrastructure to get rid of this harmful chemical."

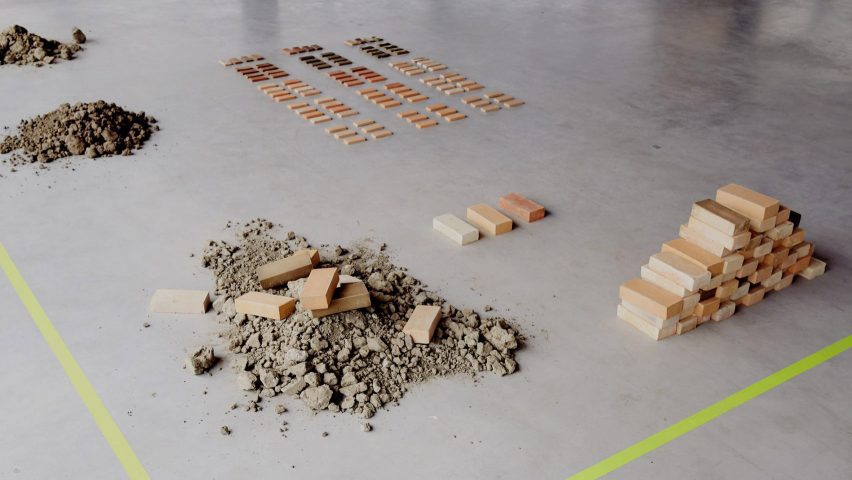

Bensdorp, a 2020 graduate from the Design Academy Eindhoven, has so far transformed three heavily polluted clay soils into her "clean bricks".

This includes one from the land around Amsterdam's Schiphol Airport, where an accident involving firefighting foam resulted in very high PFAS concentrations in the soil. Another, within the city of Doetinchem in the province of Gelderland, had 1300 barrels of PFAS firefighting foam leaking into it over many years.

Bensdorp makes the clay soils into bricks of various colours and stamps them with a mark indicating the location of origin and amount of PFAS removed.

The designer, whose work is on show at the Secrid Talent Podium at Dutch Design Week, will next be attempting to show her idea can work on an industrial scale.

For this, she will be making 50,000 bricks from one site. Here, the fumes will also be tested to validate that the production process is fully clean.

Bricks have become a focus of innovation in recent years, with several designers proposing ways to make them in a more environmentally conscious fashion. This includes a brick made with human urine, which avoids having to fire them altogether.

The photography is by Anouk Moerman unless otherwise stated.

Claybens is on display as part of Dutch Design Week 2023 from 21 to 29 October. See Dezeen Events Guide for information about the many other exhibitions, installations and talks taking place throughout the week.