Underconstruction by Ornella Stocco

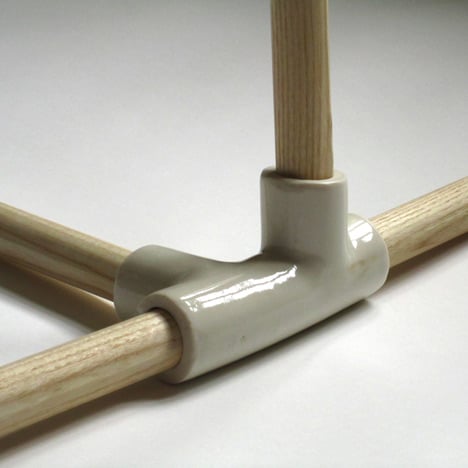

New Designers 2011: Spanish furniture and product design graduate Ornella Stocco has created a modular furniture system with joints made of porcelain.

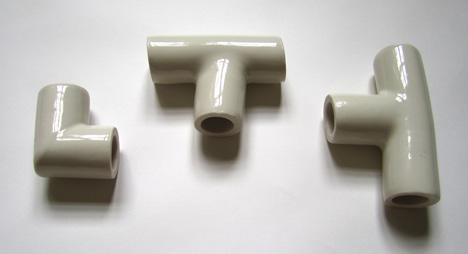

Called Underconstruction, the system includes three different joints that can be used to build and reconfigure tables, coat pegs and storage rails from wooden poles.

Stocco made the pieces from extruded porcelain, joining the tubes by hand before firing them at high temperatures in an effort to make the fragile material as durable as possible.

Transfers highlight the unusual material choice by referencing traditional Delft pottery.

Stocco designed the system, called Underconstruction, while studying furniture and product design at London Metropolitan University.

New Designers Part 2 took place from 6 to 9 July in London. See all our stories about the work on show here.

Here are some more details from Ornella Stocco:

Underconstruction: porcelain elbows for furniture assemblage

Just like plumbing fittings, Underconstruction consists of porcelain elbows that connect wood sticks in order to assemble furniture. I wanted to push forward the boundaries of porcelain’s common values by playing with its symbol of fragility and delicacy, and give a new use to it. On one hand, the porcelain elbows function as hardware fittings giving freedom to the user to customise his/her own piece of furniture. On the other, they create a familiar and warm domestic construction.

Along my design studies, I have been mostly interested in the experimentation with materials and how these can be distanced from their common assumptions and be placed in new contexts. At that moment, materials will transmit a complete different approach where the boundaries of how they should/could be used disappear. Underconstruction is one manifestation of this experimentation where the goal was to combine wood and porcelain within a functional structure by looking for the most suitable form and state of porcelain in order to make it utile. For that reason, the elbows have been high fired and therefore vitrified so they reach their most resistant strength level. The blue willows transfers immediately explain the material it’s made of.

Materials: porcelain and ash wood.