Using computer algorithms in design is like "sculpting with a new material"

Future Makers: Alessandro Zomparelli of Italian design studio MHOX, which produces customised 3D-printed fashion accessories, says designing with computer algorithms is like exploring a new material (+ movie).

"It's exciting to be a designer today, because we have digital tools that allow us to create something incredible," Zomparelli says in the the movie, which was filmed by Dezeen at MHOX's studio in Bologna, Italy.

"If you are a sculptor, then you have to know your material, you have to explore it. And using these digital tools is quite similar – there is a whole new landscape for designers to explore."

MHOX, which Zomparelli founded together with Filippo Nassetti, specialises in using generative design to create 3D-printed fashion accessories.

"We are exploring the opportunities of digital tools and 3D printing technology in product design for the body," Zomparelli says. "We are interested in exploring the aesthetic consequences of this evolution of technology."

The studio's Carapace project consists of a series of bespoke masks, which are designed and printed to order based on a 3D scan of the customer's face.

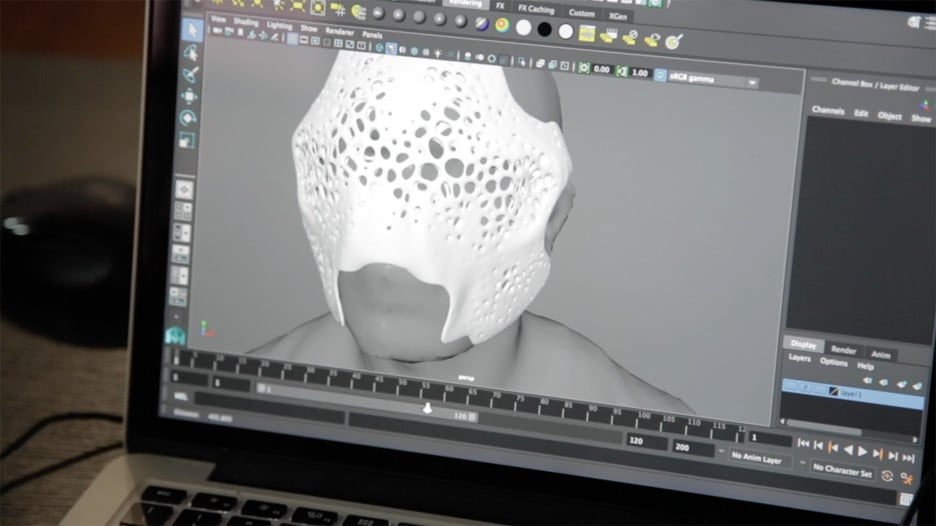

"We use a Kinect sensor," Zomparelli explains. "We then create a 3D model that is adapted to the shape [of the customer's face] using a 3D modelling tool like Maya."

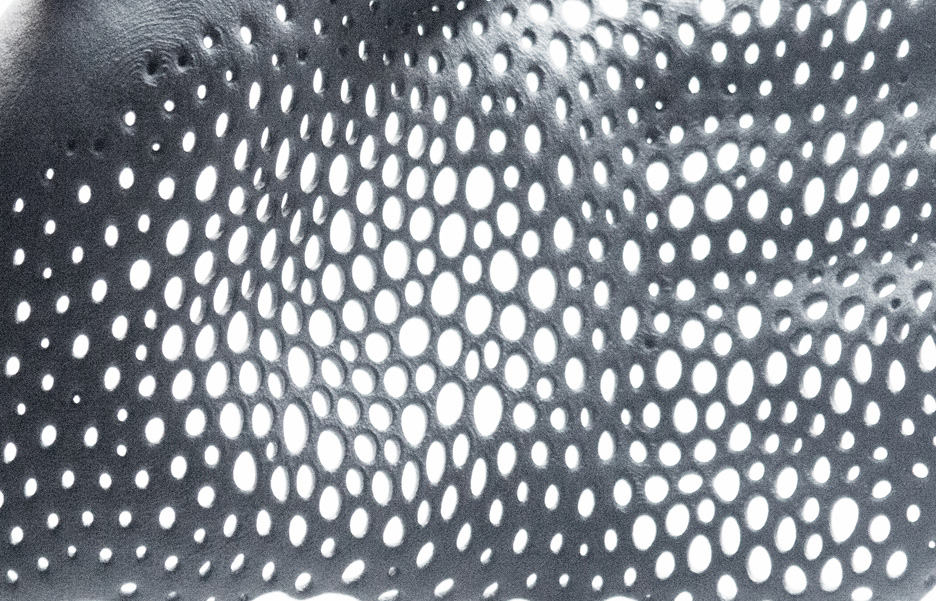

A carapace is the upper section of the exoskeleton found in arthropods such as crustaceans or arachnids. MHOX developed its own algorithm to generate unique patterns in the masks based on the microstructures found in these shells.

"We took inspiration from the exoskeletons," Zomparelli says. "Using the computer it is possible to simulate natural phenomena in a digital environment."

The Carapace masks are 3D printed by Italian company CRP Technology using a flexible composite material called Windform, which combines nylon with glass microfibres.

MHOX is currently working with CRP Technology to use the same design approach to produce wearable medical devices called orthoses, which are fitted to the body to correct movement or posture.

"We realised that this kind of process of 3D scanning and 3D generation of geometry can have a good potential for the medical industry," Zomparelli explains.

One of MHOX's first prototype orthoses is a device that prevents patients with certain neurological conditions from clenching their fists.

"It's a support for the hand for people who have to wear these kind of devices all the time in order to keep their hand in the right position," Zomparelli explains. "We use a porous surface to prevent excessive perspiration. It's also a device that is washable."

Medical orthoses are not usually very attractive. Zomparelli says that MHOX is trying to create devices that people will actually want to wear.

Subscribe to Dezeen's YouTube channel for the latest architecture and design movies

"We use a similar aesthetic for both fashion design and medical design because we want to give the opportunity to patients to wear wear fashion devices," he says.

This movie was filmed by Dezeen in Bologna. Images and additional footage used in the movie are courtesy of MHOX and CRP Technologies.

Future Makers is a collaboration between Dezeen and Autodesk exploring how designers are harnessing new digital tools and advanced manufacturing technology to pioneer the future of making things. You can watch all the movies in the series as we publish them on our YouTube playlist: