DUS Architects builds 3D-printed micro home in Amsterdam

Dutch studio DUS Architects has 3D printed an eight-square-metre cabin and accompanying bathtub in Amsterdam, and is now inviting guests to stay overnight (+ slideshow).

DUS Architects used sustainable bio-plastic to create the 3D Print Urban Cabin, which is intended to demonstrate how additive manufacturing can offer solutions for temporary housing or disaster relief.

When the cabin is no longer needed, it can be destroyed and almost all the materials can be reused.

"The building is a research into compact and sustainable dwelling solutions in urban environments," said the team.

"3D printing techniques can be used particularly well for small temporary dwellings or in disaster areas," they said.

"After use, the bio print material can be shredded entirely and re-printed into new designs."

The Amsterdam-based architecture studio is currently in the final stages of a project to build a full-size 3D-printed canal house. This smaller project offers an insight into what that structure will look like.

Located in a former industrial area, the tiny gabled cabin contains just 25 cubic metres of area – far less than the average micro home.

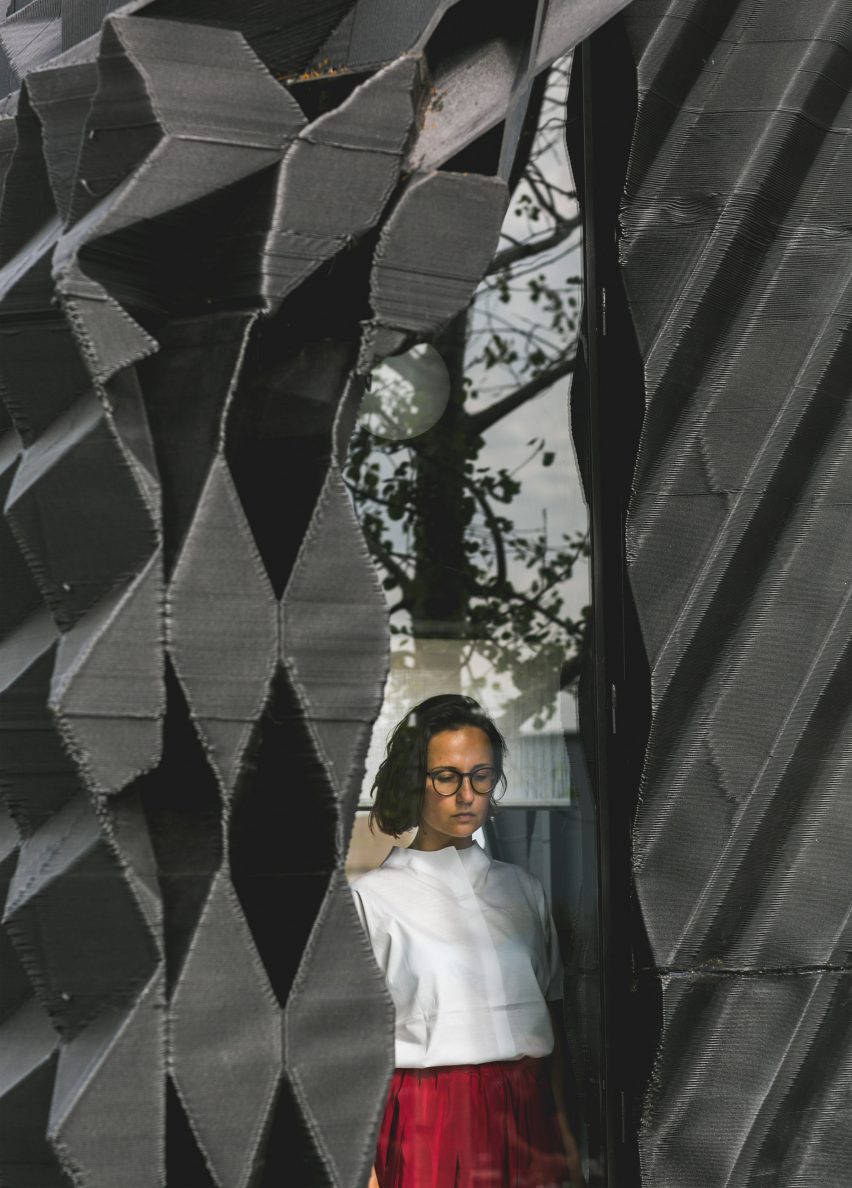

A window punctures one end, while the other integrates both an entrance and a stepped porch seating area. Its walls are patterned with angular protrusions that create a three-dimensional surface, giving the building extra structural stability.

All of these surfaces are black, thanks to the bio-based 3D-printing filament – a product with linseed oil as its main component, which the architects have been developing with major consumer manufacturing company Henkel.

A small amount of concrete was also used, to provide a durable flooring surface. It infills a patterned grid, which extends out from the cabin to form a pebbled pathway across a small garden.

"Entirely 3D printed with black coloured bio-based material, it showcases different types of facade ornament, form-optimisation techniques, and smart solutions for insulation and material consumption," said the team.

Inside, the cabin contains enough space for a bed, although this can be folded up into a seat during the day. There is no space for a bathroom, but a large 3D-printed bath is located in the garden.

"In the green around the cabin you can enjoy the sculptural printed bathtub, and watch the sunset surrounded by waving poplar trees," added the architects.

DUS Architects first unveiled designs for the 3D printed canal house back in 2013 and is aiming to complete the project early next year.

But the 3D Print Urban Cabin isn't the first completed example of the studio's 3D printing expertise – earlier this year it created a sculptural facade for a European Union meeting building, which was the first public reveal of its so-called "XXL 3D prints".

This technique uses fused deposition modelling, the same form of additive manufacturing used by most household 3D printers.

The cabin is available for short-term lets.

Project credits:

Architects: DUS architects

Design team: Hans Vermeulen, Martine de Wit, Hedwig Heinsman, Martijn van Wijk, Inara Nevskaya, Ivo Toplak, Peter Hudac, Foteini Setaki

3D printing and assembly: Martine de Wit, Jasper Harlaar, Sven de Haan, Ina Cheibas, Joe Platt, Nathalie Swords

Material development: Henkel

IT hardware: Lenovo

Concrete work: Heijmans

Bath spout: Vola

Textiles: Borre

Landscape: Delva Landscape, Boomkwekerij Ebben

Accessories: Misc store