The iPhone is "not very innovative" because it's hard to recycle, says Formafantasma

Electronics companies like Apple need to make their hardware easy for anyone to open up and take apart, according to design duo Formafantasma, who are pushing designers to prioritise recyclability following a two-year research project into e-waste.

"As a society, we have fallen in love with an idea of innovation that is not innovative," Formafantasma co-founder Simone Farresin told Dezeen. "When we talk about technology, we have a very specific idea of what constitutes innovation, and it does not consider parameters such as whether it's recyclable."

"On those terms, I could argue that the iPhone is not a very innovative product. The same with most recent smartphones."

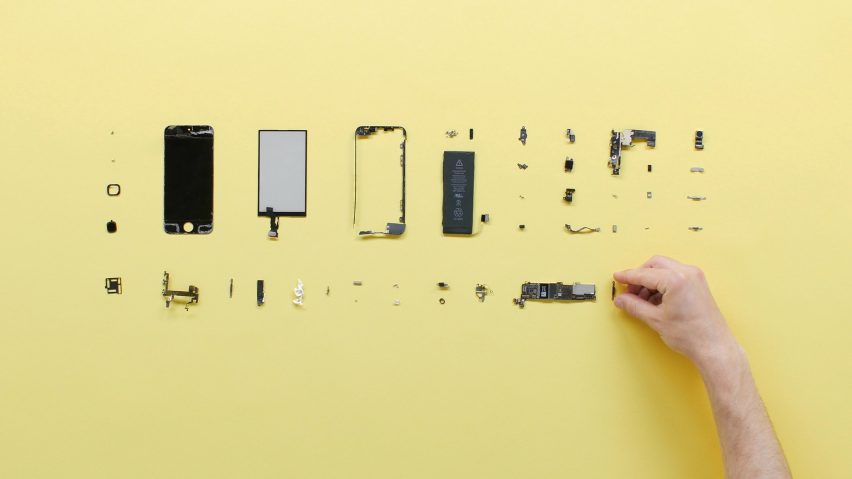

The sticking point for Farresin is that many contemporary devices are designed so that only their producers can open them up again. Apple's iPhones, for instance, feature tamper-proof custom screws and nigh impenetrable casings that make it difficult to access the battery and other components inside.

This practice undermines companies' proclaimed commitments to recycling, because "you make the object less transparent for the user, you cannot open it up and you make it more difficult to recycle", says Farresin.

While products like these might be efficiently disassembled by specially contracted recyclers or in-house programmes – indeed, Apple revealed a 29-armed robot specifically designed for the task last year (it's name is Liam) — only a minority of devices are ever returned to the companies that produce them.

"The reality is that their products are sold and distributed all over the world, including in developing countries [that don't always have access to these programmes and resources]," continued Farresin. "It is important to design products conceived for places where the ideal scenario is not a possibility."

The question of "above-ground mining"

Designing for reality rather than the ideal is one of several strategies advocated by Formafantasma in Ore Streams, a research-based project commissioned by Melbourne's National Gallery of Victoria for its inaugural NGV Triennial, which opened on 15 December 2017.

Farresin and Andrea Trimarchi, the other half of Formafantasma, arrived at the topic through a roundabout route: they were initially looking into mining, but after discovering that by 2080, our biggest metal reserves will no longer be underground, they shifted focus to what they call "above-ground mining" instead.

The Amsterdam-based Italian designers then spent two years disassembling electronic goods in their studio, visiting recycling plants in Thailand and interviewing a range of experts and sector workers.

While they were impressed by much of what they saw — including at the only electronics company to open its doors to them, Fuji Xerox, where printer components are being reused multiple times — they were also disappointed that where there were inefficiencies in the recycling process, they often came down to product design.

It inspired Farresin and Trimarchi, who founded Formafantasma in 2009 after graduating from Design Academy Eindhoven, to propose a new approach for designers and developers of electronic products. It is explored in one of the videos the pair is showing in the Triennial exhibition, where it plays alongside a poetic range of office furniture they've created using e-waste.

Four steps for recyclable design

Farresin and Trimarchi's strategies constitute small, concrete steps that they believe would be easy to implement but have a big impact.

The first, mentioned already, is to design easily openable products that allow for the quick removal of batteries and other hazardous components, which can potentially explode during the recycling process and, if not disposed of correctly, cause soil or water pollution. A second, related point is to make sure these components are adequately labelled.

"It is not a problem in developed countries, because people are trained, there are recycling centres and so on," said Farresin. "But in developing countries, if you don't know and you break the wrong part, it's dangerous. We have been disassembling several electronic goods here in the studio and made videos of it. I can tell you, there are some parts you'd have no idea were toxic."

Their third recommendation is to avoid glue, which has been used more frequently as electronics have gotten smaller but makes pieces more difficult to pry apart. Instead, the duo advocate "space-efficient" connections or clamping systems.

Their fourth idea would involve a group effort: the development of a universal colour-coding system enabling different materials to be easily identified and sorted. To illustrate how much this is lacking in the recycling process, Farresin gives the example of common electrical cables coated in black rubber. Their dark colour and opacity means they aren't recognised by visual detectors and can end up in the wrong waste stream.

The future of recycling is in pieces

There's a reason Farresin and Trimarchi are preoccupied with improving access to the insides of devices in their proposals. The duo see the reuse of componentry rather than recycling of minerals as the future — just like they witnessed at Fuji Xerox, with its reincarnated printers.

Currently in Western countries, the common approach to recycling electronics is to shred the entirely of the device (with hazardous parts removed) and then sort the metals using a system of magnets. An investigation by Motherboard in 2017 found that Apple demanded "must shred" agreements from all its recycling partners in the USA.

However, this process uses a lot of energy and causes the minerals to be degraded. If the trend reverses, it will mean the world's more advanced economies will be taking a leaf out of the books of low and lower-middle-income countries, where reuse is already widely practiced — despite the obstacles to recovering the parts.

"There are a lot of things that need to be regulated, but the trend for the future is the recycling of components, not just materials," said Farresin. "Brands will set up their own collaborations with recyclers and as much as possible recycle components."

Read on for the full transcript of the interview with Simone Ferresin.

Rima Sabina Aouf: Where did the idea for Ore Streams come from?

Simone Ferresin: Our initial starting point for the project wasn't to look into recycling, but into mining, because Australia [where the work is being shown at the National Gallery of Victoria] is the only first-world country that is still extracting minerals. But we learned after reading on the topic that by 2080, we will have mined so many minerals, that the biggest metal reserves will be above ground, and the recycling to collect metal will become more efficient. So we thought it was more interesting to focus on what we ended up calling "above-ground mining". We decided to focus on electronic waste specifically because it's the fastest-growing stream of waste, and also because our entire life both as citizens and designers revolves around digital tools.

Rima Sabina Aouf: We often think of recycling as the solution to the problem of e-waste, but what you seem to be saying with Ore Streams is that there are issues with that recycling process that we're not thinking about enough. Is that right?

Simone Ferresin: What we're saying is that we could do better. Legislation-wise, there are still a lot of problems and a lot of illegal shipment to developing countries. Also, we design products sourcing materials globally and to be sold globally, but they're not being conceived as such. So when it comes to recycling these products, it's easier to recycle them in developed countries and much more difficult in developing countries.

Rima Sabina Aouf: Why do so many of our electrical products end up in the so-called developing countries and why is that a problem?

Simone Ferresin: There are several reasons why. Simply, the best way to recycle stuff is with manual labour, and of course, labour is expensive in developed countries.

In the beginning, the legislation wasn't in place to prevent the exporting of e-waste to developing countries, but in the beginning of the 90s the Basel Convention was signed a lot of countries from all over the world, though only some of them have ratified it. Europe is doing quite well, but the United States and Australia are two of the places where the convention is not really well enforced.

The best way to recycle stuff is with manual labour, and of course, labour is expensive in developed countries

One of the reasons it is happening still, even with laws in place, is because there are not enough controls at the borders and it is still cheaper to dump the stuff over there, despite the fact that there are precious metals in these products. Another thing that is happening recently is that things are shipped abroad as second-hand as a guise for dumping waste.

Rima Sabina Aouf: In what ways have you seen e-waste recycling differ between the developed and developing worlds?

Simone Ferresin: What we currently do in developed countries is basically shred everything after the hazardous components are removed, and then sort the metals. I think more and more in the future brands will set up their own collaborations with recyclers and as much as possible recycle components, which is what the developing world are already doing, like in China and Africa. Although we did hear some horror stories out of China of components being reused for military purposes and stuff like that, where you absolutely want to be sure the components are new and certified. There are lot of things that need to be regulated, but the trend for the future is the recycling of components, not just materials.

Rima Sabina Aouf: And you believe recycling is getting more efficient?

Simone Ferresin: It is already quite efficient, but where it is not efficient, often it is because of design.

Rima Sabina Aouf: So what are some of the things designers should take into account to ensure their products can be recycled all over the world?

Simone Ferresin: The first one is the positioning of the batteries and hazardous components. Often these objects are placed in difficult positions to reach or they are glued to other components. Or, like in the iPhone, they're encapsulated in a design that is not easy to quickly open up and remove the hazardous components. These parts are the ones recycled with manual labour, including In Europe, the US and other developed countries. The first necessity is that these products are designed in such a way that allows the quick removal of these components, because they can cause pollution or explode during the recycling process.

The miniaturisation of electronics is becoming a problem, because then more glue is used

Second, the miniaturisation of electronics is becoming a problem, because then more glue is used in the process of assembling products. This is sort of fine in developed countries, where we have several technologies that work to separate the materials, but in developing countries, products are recycled with the aim of obtaining components, not to recycle materials directly. So in that process components that are glued together are more difficult to separate.

There are also some other basic issues — for instance, a lot of brands use custom-made screws or connections, which creates the need for more tools to remove them. In developing countries, some NGOs are establishing workshops but having trouble getting the right tools to open up these products.

Rima Sabina Aouf: How else can designers make sure they’re not exposing people to hazardous materials somewhere down the line?

Simone Ferresin: There is not a correct labelling system for hazardous components. Again, it is not a problem in developed countries, because people are trained, there are recycling centres and so on. But in developing countries, if you don't know and you break the wrong part, it's dangerous. We have been disassembling several electronic goods here in the studio and made videos of it. I can tell you, there are some parts you'd have no idea were toxic.

Another problem is that sometimes materials are mixed in a weird way. For instance, in washing machines, concrete is mixed with metal in the weight that makes the machine stable. That is a problem, not only because you cannot recycle it but because it can end up in the wrong stream of waste together with ferrous materials.

In our video, we've outlined simple strategies for designers to address these problems. One is a systematic approach to visual recognition. To give you an example, black cables in rubber are common, but they're difficult to recognise and sort, so they can end up in the wrong stream of waste. If all electric cables could be coloured in a specific way that indicates their makeup, then they could be separated more efficiently.

Rima Sabina Aouf: What about major companies like Apple and Samsung, which produce more products than anyone else in this sector — what responsibilities do they have with regard to e-waste? Are they doing enough?

Simone Ferresin: I'm sure they are very busy with it. In terms of the law, the responsibility of recuperation of electronic waste is on the producers, so literally if you have a product at home from a certain brand, you can ask them to collect it. It is their responsibility.

For this project, we tried to contact Apple and Samsung, but the company that opened their doors to us was Fuji Xerox, the printing company. We were totally surprised at the work they are doing. They've established a brilliant system. For them it's a bit easier because they have one typology: printers. They collect them and send them to recycling centres in several places. The products are completely disassembled, and they don’t recycle the materials immediately; they recycle the components. As far as we know they’re the only brand doing it. The components of their printers are reused to make their own printers again, I think to a maximum of four times, at which point the components are recycled for materials. The company don’t own only the production sites, they also own or have very good partners for the recycling of components.

From our experience, the communication between producers and recyclers is usually lacking. It's in the hands of the producers to establish that link.

Rima Sabina Aouf: To take the iPhone as an example again, you mentioned the casing is an obstacle to retrieving the components for recycling, but some say the more solid casing was a design decision to help make the phone more waterproof, and therefore give it a longer life. Could that have been a good decision?

Simone Ferresin: From our perspective, no, because you make the object less transparent for the user, you cannot open it up and you make it more difficult to recycle. But it also depends on the company and how they establish their recycling structure. Apple has the potential to establish its own recycling facilities or team up with recyclers to have their own specific recycling section. But that still only works when you consider the ideal scenario of products being returned to them. The reality is that their products are sold and distributed all over the world, including in developing countries. I think it is important to design products conceived for places where the ideal scenario is not a possibility. So it's a bad decision.

Rima Sabina Aouf: You mentioned the possibility of increased partnerships between producers and recyclers. That seems like something that would be good for these major companies' PR. So why haven't we seen more of that?

Simone Ferresin: Companies won't publicise their recycling efforts, for the simple reason that they are scared to be publicly shamed. They know that they can never make it right, so they don't talk about it. They do it, because they do think it is important to do, but they don't say it, because it's too risky communications-wise.

As a society, we have fallen in love with an idea of innovation that is not innovative

Rima Sabina Aouf: Why do you think it is important for designers to create their products with their future recycling in mind?

Simone Ferresin: As a society, we have fallen in love with an idea of innovation that is not innovative. When we talk about technology, we have a very specific idea of what constitutes innovation, and it does not consider parameters such as whether it's recyclable. On those terms, I could argue that the iPhone is not a very innovative product. The same with most recent smartphones. The risk is that we fall in love with an idea of technology that is just an idea, a modernist construct of efficiency. It is just one idea of what progress looks like, and we need to expand it.

Rima Sabina Aouf: Tell me about the approach you took to translating the research into physical objects for the exhibition.

Simone Ferresin: One of the requests from the museum in the commission was to have some furniture pieces for their collection. We didn't want to do household furniture; we wanted to work with office furniture, partly because of the simple connection that electronic products are often used in the office, but also because of what I was saying before about modernism. The office is where you see the pragmatic approach of modernism in terms of quantification, use of space, functionality and so on. We feel that the same pragmatic approach based on quantification and supposed efficiency is also used with natural resources, so we thought the office was the right environment to express our investigation.

The idea in all the objects is that you have elements of electronic waste that are not upcycled; rather, they are intrusions into the objects. For instance, the table has the aeration grid of a microwave in one of the legs, and the tabletop is seated on iPhone cases, two of them gold-plated. Gold scavenged from circuit boards is recurring as a finish throughout the series: most visibly, as cladding on the inside of a leather trash bin, as one thin section of the CNC-milled aluminium chair and in two iPhones and a keyboard placed in the table and cubicle, respectively.

All the objects have these extra external elements in place. We started imagining that all these objects we have around the office became integrated with waste in weird ways, almost inlaid within the objects. We chose objects that were familiar within the office, but becoming slightly odd and unfamiliar — the iPhone is under rather than on top of the table, you have the aeration grid that doesn't serve to do anything on the leg of the table. This is something we often do in our work — you start wondering why these elements are there and why they are placed in that specific way. For us is a way to have the viewer engaging with questions, or at least start wondering about the reasons behind these choices.

We used the images of Mars printed on the surfaces in the same way. That is a reference to the fact that gold arrived on earth via meteorite rain that crashed against the planet. On a subliminal level, having these images evokes a feeling of deployed earth or an empty planet, which we thought moved the objects from being only functional to an evocative level.