Pike Loop by Gramazio & Kohler

Construction will begin on a wall to be built entirely by a robot - designed by Swiss architects Gramazio and Kohler - in New York later this month.

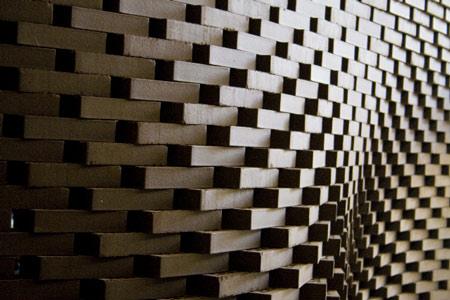

Above and top image: Structural Oscillations, at the 2008 Venice biennial.

The same robot, R-O-B, was used to construct the award-winning Structural Oscillations installation at the 2008 architectural biennial in Venice (shown here).

Above: trailer-mounted R-O-B constructing Pike Loop.

The new sculptural brick wall - called Pike Loop - will be constructed on Pike street, New York, in full public view over a period of four weeks. Construction will commence on 5 October.

Above: trailer-mounted R-O-B.

The robot has been mounted on a low-bed trailer, allowing it to manoeuvre along the wall as it places more than seven thousand bricks.

The wall is the next step in three years of research into full-scale digital fabrication in architecture using industrial robots, conducted by the architects at ETH Zurich.

Gramazio and Kohler will also be exhibiting their research at the Storefront for Art and Architecture gallery in New York.

See also our story about a similar robot-built brick wall built at the Graduate School of Design at Harvard earlier this year.

Further details from the Storefront Gallery:

--

On September 29, Storefront for Art and Architecture will inaugurate a new exhibition showcasing research conducted over the past 3 years at ETH Zurich by Swiss architects Gramazio & Kohler into full-scale digital fabrication in architecture using industrial robots. At the same time, construction work will begin on Pike Loop, the first architectural project to be built on site by an industrial robot in the US.

Located on Pike Street, the robot, R-O-B, will work for up to four weeks—in full view of the public— to construct a brick wall, a highly sculptural response to the specific identity of the site. The same robot unit recently built the award-winning installation, Structural Oscillations, at the 2008 architectural biennial in Venice. For the Pike Loop installation, more than seven thousand bricks aggregate to form an infinite loop that weaves along the pedestrian island. In changing rhythms the loop lifts off the ground and intersects itself at its peaks. The installation was coordinated through the New York City Department of Transportation’s Urban Art Program.

Developed through their research at ETH Zurich Faculty of Architecture, Switzerland, Gramazio & Kohler's work explores highly complex architectural artifacts, built by industrial robots typically used to assemble automobiles and perform other high-precision tasks. The accuracy, strength and speed of these robots allow them to fabricate architectural forms of unprecedented complexity and intricacy. Gramazio & Kohler's work represents the cutting edge of innovation in the field of digital fabrication in architecture. For many years architects have relied on digital manufacturing processes such as CNC milling or 3D printing as a tool for formal research at model-scale. For the first time, Gramazio & Kohler’s work explores the potential of mobile digital fabrication techniques that can fabricate at 1:1 scale on site.

The exhibition at Storefront Gallery will present the results of Gramazio & Kohler’s ongoing research into digital fabrication in architecture at ETH Zürich Faculty of Architecture. The same robot, R-O-B, unit recently built the award-winning installation, Structural Oscillations, at the 2008 architectural biennial in Venice.

Exhibition location:

Storefront for Art and Architecture, 97 Kenmare St., NYC

Exhibition opening reception:

Sept. 30, 7p.m. (Exhibition ends Nov. 14, 2009)

Installation location:

Pike St. between Division St. and East Broadway

Installation construction period:

Oct. 5 – Oct. 27

Inauguration of completed installation:

Oct. 27, 7p.m.