"Food is the next frontier of 3D printing"

News: 3D printing expert Janne Kyttanen has produced prototype printed pasta, breakfast cereal and burgers to demonstrate how advances in 3D printing could transform the way we eat (+ interview + slideshow).

Kyttanen, co-founder of design studio Freedom of Creation and creative director of printer manufacturer 3D Systems, told Dezeen: "Food is the next frontier. We’re already printing in chocolate, so a lot of these things will be possible in the next few years."

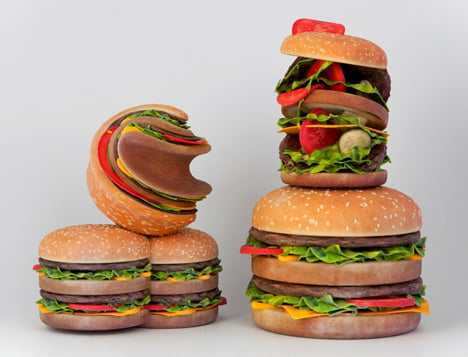

To illustrate the possibilities, Kyttanen has 3D-printed models of pasta in plastic and cheese burgers in plaster. "I printed burgers just to create an iconic image and make people realise that one day we will be able to 3D-print a hamburger. And once you do, you don’t want to print a traditional hamburger; you can print the weirdest thing you can imagine."

Kyttanen believes it's only a matter of time before technology enables us to print molecules in combinations that produce tasty meals. "At the moment the technologies that we use are very, very crude. So they solidify matter, either by powder or by liquid or extruded filaments and so forth," he said. "But at the end of the day it’s just atoms and molecules, so [one day] we will have technology where you can just move molecules or you can move atoms."

However, he concedes that we're still a long way off downloading burgers to print at home and that only a viable market will push companies to pursue the technology. "If you can’t find a good business model for it, it won’t happen," he says, suggesting that possible avenues for firms to explore would be fun items and novelty experiences, like having your own head scanned and printed in chocolate.

Kyttanen also believes design can learn from food when it comes to copyright, hinting that the sharing of design ideas should as acceptable as sharing recipes. "I look at design and for me, it's like food," he says. "It’s very fast and everything I need is in my computer, and I can make whatever I want, whenever I want."

"If you look at all the recipes on the internet, everything is free and everything is shared," he continues. "Who’s going to come to your house, watch you make a pasta bolognese and say, 'you know what, you can’t make that'?"

See our previous interview with Kyttanen in October, when he told us that 3D printing products at home is "cheaper than shopping".

We've been closely following the rise of 3D printing and reporting on all kinds of uses for the technology, from a 3D-printed dress for burlesque dancer Dita Von Teese to printing plastic weapons – see all 3D printing.

Other unusual food we've featured includes an edible desk lamp and an aerosol spray that lets users enjoy alcohol without the risk of a hangover – see all food design.

Photography is by Ivo de Bruijn.

Read the full interview below:

Ben Hobson: Tell me about the images you’ve sent us.

Janne Kyttanen: We have all these different avenues in which 3D-printing technology is moving. We’ve explored all different kinds of products and different materials, but everything is going in the same direction, which is really speed and disposability, whether it’s prototyping something or making an end product or something else. Food is the next frontier.

The images that I sent you are just conceptual things. The pasta is not made from pasta - it’s made from plastic. But I wanted to pinch people a little bit and make them realise that we are able to do these things. We’re already printing in chocolate, so a lot of these things will be possible in the next few years. I’m just conceptually trying to see what could happen, which is why I printed burgers just to create an iconic image and make people realise that one day we will be able to 3D-print a hamburger. And once you do, you don’t want to print a traditional hamburger; you can print the weirdest thing you can imagine.

Ben Hobson: How do you go from printing a burger in plastic to actually printing one you can eat?

Janne Kyttanen: At the moment, the technologies that we use are very, very crude. So they solidify matter, either by powder or by liquid or extruded filaments and so-forth. But at the end of the day it’s just atoms and molecules, so [one day] we will have technology where you can just move molecules or you can move atoms. At the end of the day we will be able to do that. And how and what [we will make] I don’t know. It will find its own shape, but I’m just more concerned to conceptually ask these questions.

Ben Hobson: What kind of future do you see for 3D-printed food? Will we all be printing out food rather than cooking with traditional methods?

Janne Kyttanen: I don’t think anything will be replaced. People always ask me, is 3D printing going to make all these Chinese mass manufacturing people unemployed? I don’t think so. I think these jobs will remain. Our technology is just one additional way of making things. It’s just a nice new thing.

Ben Hobson: What’s the timeframe for 3D-printed food? How long before it’s mainstream?

Janne Kyttanen: We are already printing chocolate. Any matter that you can put into an extruding nozzle you can already print in. You can make anything you want, whether it’s jelly or chocolate or some pastries or some marzipans or whatever, in principle you can make it. But there have been very few parties developing technologies towards this. We as a company [3D Systems] are moving ahead on all fronts democratizing access to 3D printing, and hopefully there are also others doing their own endeavours.

Ben Hobson: So how far off is a 3D-printed burger?

Janne Kyttanen: I wouldn’t be able to say that. A lot of these things are quite trivial. It matters what kind of equity, what kind of financial push you have – most of the time, that's the driver. If you can’t find a good business model for it, it won’t happen. Like chocolate, for example; people have been printing chocolate for years but there hasn’t really been any boost in it. Maybe they haven’t found the right business model.

Ben Hobson: Are there any particular business models that you think are worth exploring?

Janne Kyttanen: Oh yes, for sure. If you’re talking about chocolate for example, there are a lot of expensive high-end chocolate makers out there, so I can imagine getting your own head scanned and then printed as a chocolate cake. It’s also a lot of fun.

There’s a lot of debate around “this is my design, you can’t touch it,” but I hope brands will start getting more open-minded. Let's take shoe manufacturers, for example. People can already customise their own shoes, so how fun would it be if you could buy a pair of Nike sneakers, but you could also download Nike sneakers to your home and you can print them and eat them.

Ben Hobson: How would 3D printing with food differ from other sectors?

From the creative standpoint, I’ve always been pro freedom and not so much about constraining people’s creativity. So where are we headed in design? There’s always been debate about if I design something, I put it on the market and somebody will see me and they own the patent or they put it on the market before me, they have the copyright or IP or whatever.

But with food it’s quite interesting: I can design anything that I want and I can eat it, and when you talk about the forms and the shapes and the designs, you can design whatever you want and then it is gone.

I look at design and for me, it's like food – it’s disposable. It’s very fast and everything I need is in my computer, and I can make whatever I want, whenever I want. And then you have the other crowd who are more worried about, you know, “this is my design, you can’t copy it, you can’t do this and this.”

So food really changes everything. If you look at all the recipes on the internet, everything is free and everything is shared. Who’s going to come to your house, watch you make a pasta bolognese and say, “you know what, you can’t make that”?