Researchers find bioplastic drinking straws intact after over a year buried underground

The 5 Gyres research institute says bioplastics are "not a silver bullet solution" for plastic pollution, following a study that raises concerns about so-called biodegradable products.

In its Better Alternatives 3.0 report, the Californian non-profit found that while bioplastics degrade faster than their fossil-derived counterparts, some degrade much slower than others.

The study found that some bioplastic packaging did not decompose after being buried underground for more than a year, regardless of the climate and soil conditions.

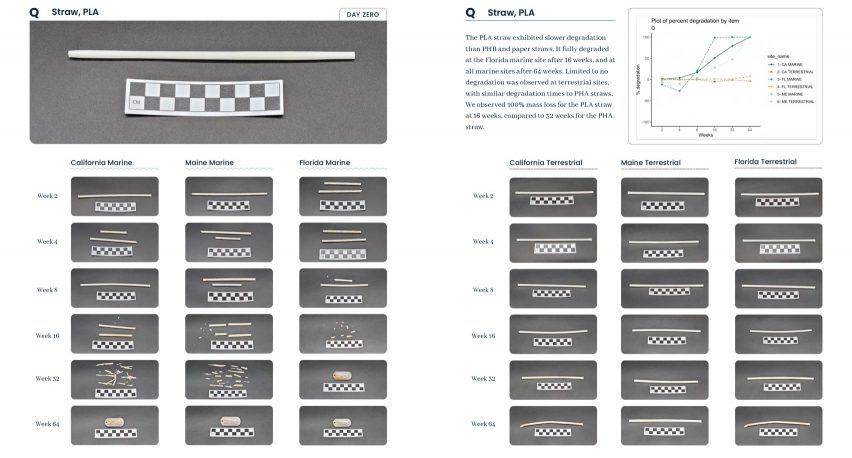

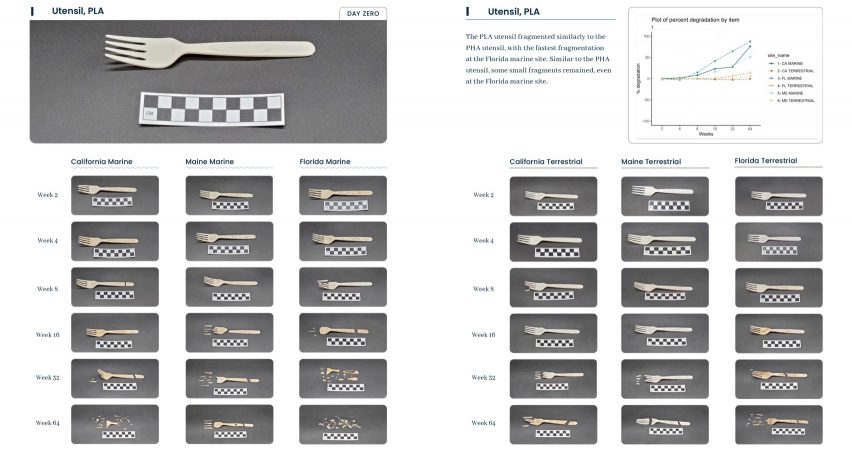

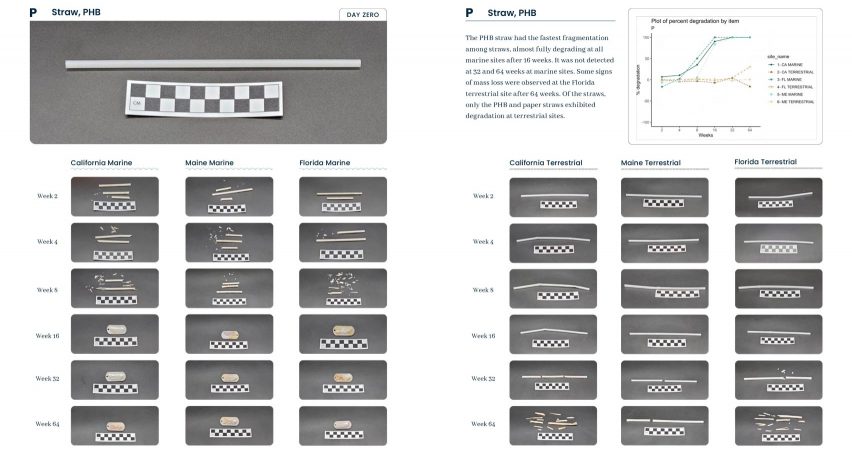

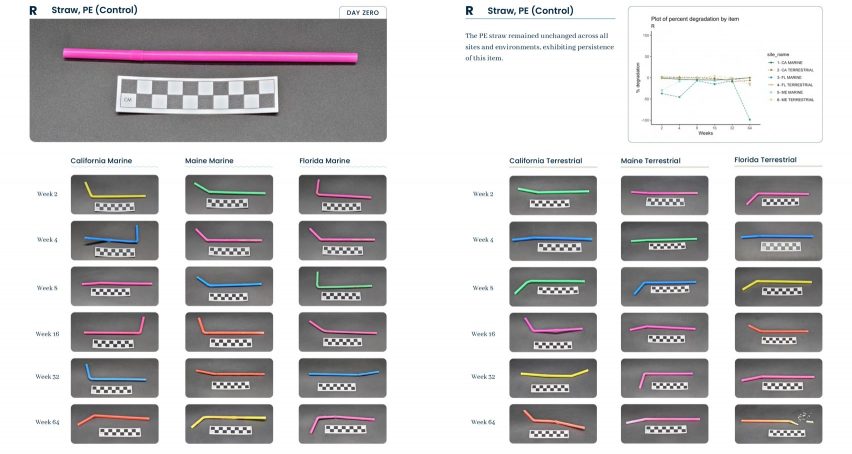

Researchers at 5 Gyres tested the degradation of 22 types of single-use packaging, with each type tested in both soil and sea for a total of 64 weeks, on sites in Florida, California and Maine.

In all three locations, straws made from polylactic acid (PLA) – a bioplastic made from corn starch or sugar cane – decomposed in the ocean but remained largely intact when buried underground.

Other common types of bioplastic packaging showed little or no signs of degradation after 64 weeks in soil, with forks, bottles and tampon applicators among them.

Lisa Erdle, director of science and innovation at 5 Gyres, said the results prove that bioplastics are not a one-size-fits-all fix for plastic pollution, despite what their biodegradable labelling might lead people to assume.

"There is no silver bullet solution for the plastics crisis," she said. "Instead, we need targeted solutions that address each sector of plastic use in society, from textiles and tyres to agriculture and electronics."

However, Erdle suggested that bioplastics can "offer potential to mitigate harm in specific cases".

"There are opportunities for upstream innovations across all sectors," she explained. "And for some sectors, bioplastics offer an alternative to traditional plastics."

The study backs up this claim. Among the 22 object types tested were three made from polyethene, or PE, a thermoplastic derived from petroleum. Film, forks and straws made from PE failed to degrade at any test sites, either terrestrial or marine.

While the bioplastics all degraded faster, some types were significantly more successful than others.

While the PLA straws failed to degrade in soil, alternatives made from polyhydroxybutyrate (PHB) – a bioplastic produced by bacteria – biodegraded either fully or partially at all test sites.

The results from different types of bioplastic film were equally varied.

PLA fragmented far slower than polyhydroxyalkanoate (PHA), another bioplastic produced by bacteria. Fragments of PLA remained at all test sites after 64 weeks, while the PHA was no longer detectable at the Florida marine site after just eight weeks.

The test objects also included paper straws, which were found to be similar to PHB in terms of degradation, and bamboo forks, which were the slowest to degrade of all the utensils.

According to Marcus Eriksen, co-founder and researcher at 5 Gyres, the results prove the need for greater transparency and clearer messaging in how disposable products are used and marketed.

He believes that terms such as "biodegradable" or "compostable" are not clear enough for manufacturers or consumers.

"Our research shows that real-world factors greatly impact what happens to a product if it ends up in the environment," Eriksen said.

"An item may be advertised as biodegradable or compostable, but under what conditions? We need greater transparency and truth in advertising about the things we buy."

With this in mind, many designers have focused instead on using bioplastic to make long-lasting products, with recent examples including furniture by German designer Basse Stittgen and textiles from Copenhagen-based Natural Material Studio.

All images are courtesy of The 5 Gyres Institute.