3D printing is "bringing the factory back to the individual"

News: cheap 3D printers mean manufacturing can again take place at home as it did before the industrial revolution, according to MakerBot Industries CEO and co-founder Bre Pettis (+ audio).

Above: MakerBot CEO Bre Pettis talks to Dezeen editor-in-chief Marcus Fairs

"Before the industrial revolution everybody did work at home; there was a cottage industry," said Pettis (pictured above), who spoke to Dezeen today at 3D Printshow in London, where his company launched a new desktop printer costing $2,200. "Then you had to go to the factory to work. Now we're bringing the factory back to the individual."

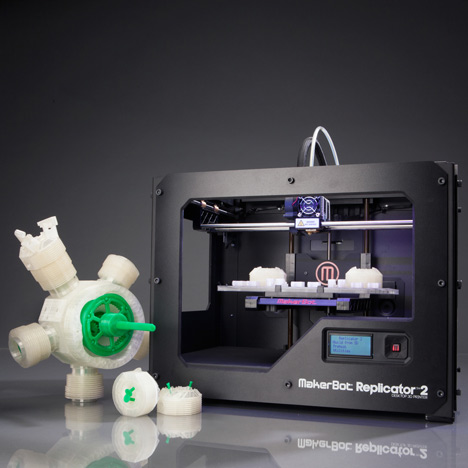

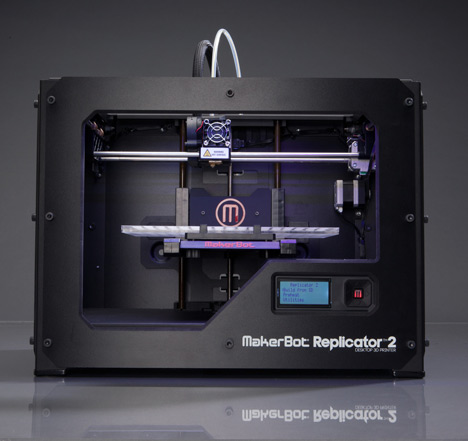

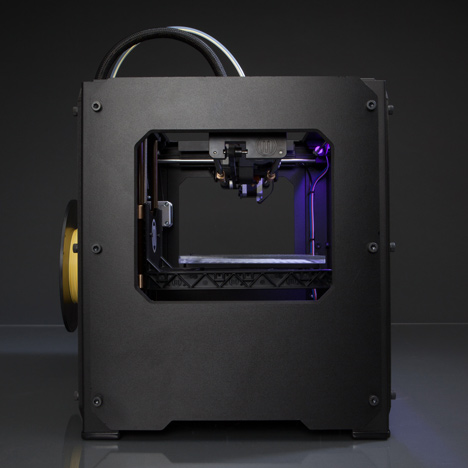

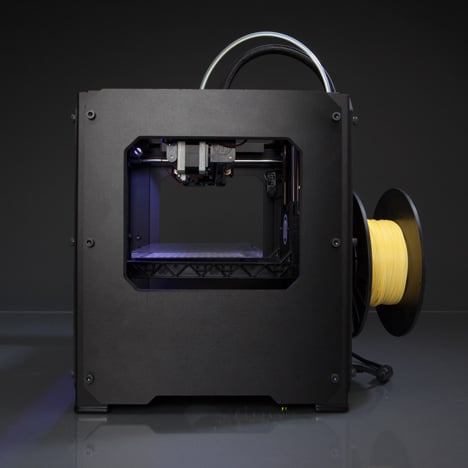

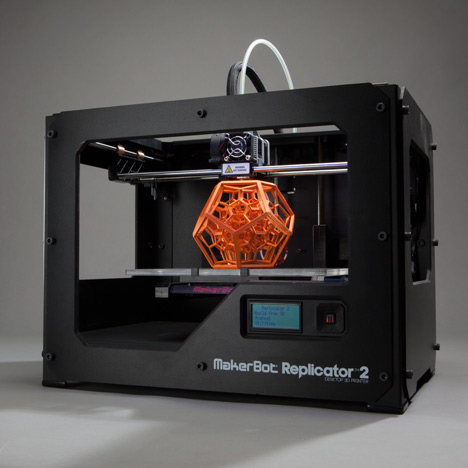

Pettis was in London to unveil MakerBot's Replicator 2 3D printer, which he claims is the first affordable printer that does not require specialist knowledge to operate. "We've just put the factory in a microwave-sized box that you can put on your desk and have at home," said Pettis.

Brooklyn-based MakerBot was founded in 2009 with the goal of producing affordable 3D printers for the home and it has become one of the best-known brands in the rapidly expanding 3D printing and open-source design movement.

Pettis claimed that 3D printing was now advanced enough to produce consumer items on demand; last month the company opened its first store in New York, selling MakerBots and products printed in store on the devices. "This bracelet I'm holding took fifteen minutes to make," he said.

3D Printshow is the UK's first exhibition dedicated to 3D printing and runs until 21 October at The Brewery, London EC1.

3D printing and open design have been hot topics recently, with several projects at the Istanbul Design Biennial exploring possible applications for the technology and gun enthusiasts releasing blueprints to print guns.

Here's a transcript of the interview, conducted by Dezeen editor-in-chief Marcus Fairs:

Bre Pettis: "I'm Bre Pettis, CEO of MakerBot Industries and we make MakerBots. We just came out with the MakerBot Replicator 2. It's a desktop 3D printer, which means you can have ideas and make them too. You can create models and 3D print them. And it's an exciting time because this technology used to be really big machines that were inaccessible in elite institutions and now you can just have one on your desktop or on your coffee table at home and you can just make the things."

Marcus Fairs: "Do you think this is the first machine that's consumer friendly? You don't need to be a geek, you don't need to be an expert programmer to buy and use this machine – have we got to that stage yet?"

Bre Pettis: "Yes, the thing that's most exciting for the average user is that we just launched a whole software suite called MakerWare, and it's makes it so much easier. You literally just drag and drop, you position it how you want it and you press make, and it just does it for you. So it's gone from a command-line tool, which is kind of hard to use, to a super easy, really nice software package that makes it easy for everyone to make the things they want."

Marcus Fairs: "People are getting very excited about 3D printing and other types of open-source manufacturing. Is that excitement a bit premature or is there really going to be a revolution in the way that objects are designed and manufactured?"

Bre Pettis: "Well, it's interesting. Before the industrial revolution everybody did work at home, there was a cottage industry. And then when the Jacquard loom and these kinds of things came along, you had to go to the factory to work. But we've just put the factory in a microwave-sized box that you can put on your desk and have at home. So it's an interesting kind of cycle of life of manufacturing now that we're bringing the factory back to the individual."

Marcus Fairs: "And how much do you think this will change the existing structure where you have a designer who designs a product and a factory or brand who manufactures it – how will that existing top-down model be changed by this kind of technology?"

Bre Pettis: "So industrial designers, engineers and architects are actually the ones [whose] whole workflow has changed by this. They used to have to have an idea, send it off to a modelling house, have it take a couple of weeks or a month and then iterate on a monthly cycle. With a MakerBot you iterate on an hourly cycle, in some cases minutes – this bracelet I'm holding took fifteen minutes to make and I'm just cranking them out all day here.

"So for the people who are making products, this just changes their life. It makes everything so much faster, so much easier, so much more accessible. If you have one of these on your desk you can actually try making the things that you're working on, and if you don't like them you can throw them away, you don't have to sign up for a service or have to stress out about how much it costs; it's inexpensive. You can fail as many times as you need to to be successful."

Marcus Fairs: "But you're talking about prototypes. I mean, how far away are we from finished products being printed on demand for consumers?"

Bre Pettis: "So in New York City we just opened a retail store, and we do two things there – we sell MakerBots, and we sell things made on a MakerBot, and we literally have a bank of MakerBots that just make things 24 hours a day for the store."

Marcus Fairs: "And what are the best-selling products that you make?"

Bre Pettis: "Right now the best-selling products are jewellery and we have this little contraption that's like a heart that's made out of gears, and people really like that too, it's made by a designer named Emmett."

Marcus Fairs: "So it's still sort of small products, sort of novelty value products – what about the huge industrial applications, the mass applications, the larger products?"

Bre Pettis: "The true MakerBot operator has no limitations. This machine we just launched has a massive 410 cubic inch build volume, which means you can actually make really big things, you can make a pair of shoes if you want to. The cool thing is that if you want to make something bigger, you just make it in component parts, and then you either make snaps, so it snaps together, or you glue it together and you can make things as big as you want, if you make it in components."

Marcus Fairs: "So this has just come out and how much does it retail for?"

Bre Pettis: "This retails for $2,200, and it's really a great affordable machine that's also just rock solid. We're really proud of it."