Adidas shapes Futurecraft 4D shoe soles using light and heat

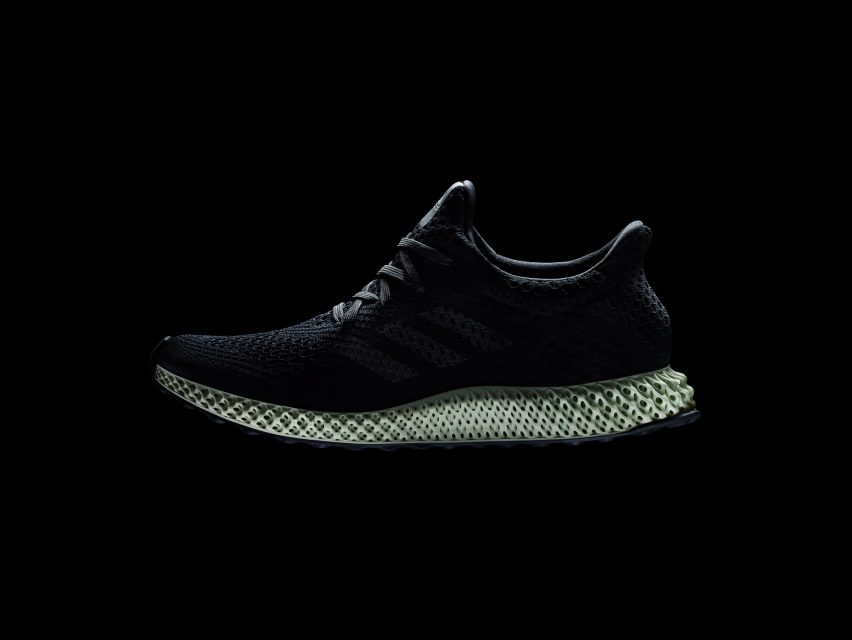

Sports brand Adidas has unveiled designs for trainers with latticed plastic midsoles, which are shaped using a new additive-manufacturing technique that "overcomes shortcomings" of 3D printing.

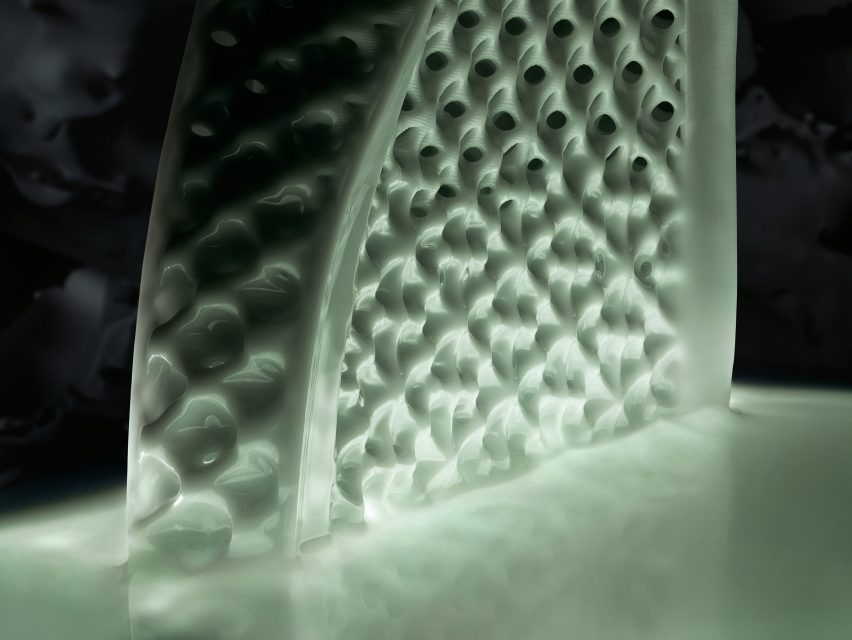

The soles of the Futurecraft 4D running shoes are formed by a process called Digital Light Synthesis, developed by Silicon Valley tech firm Carbon.

The technique uses light to shape a specially developed liquid resin that has elastic properties, then heat to set the material.

As a result, the midsole can provide different levels of cushioning and stability across a single element, which Adidas said is almost impossible to achieve through mass production with 3D printing.

The brand revealed it is "officially departing from 3D printing" now that it has found a production method that it believes is faster, more reliable, provides better surface quality and allows for more colour options.

"With Digital Light Synthesis, we venture beyond limitations of the past, unlocking a new era in design and manufacturing," said Eric Liedtke, Adidas' group executive board member responsible for global brands. "One driven by athlete data and agile manufacturing processes."

Adidas used its archive of running data to design the optimum shape for the midsoles. Digital Light Synthesis also allows the brand to easily alter the designs and create bespoke footwear for individual athletes.

"Unlike any traditional manufacturing technology, Digital Light Synthesis allows adidas to precisely address the needs of each athlete in regards to movement, cushioning, stability, and comfort with one single component," said Adidas.

The first 300 pairs of Futurecraft 4D shoes will be released in April 2017 for friends and family, followed by over 5,000 pairs for general sale towards the end of 2017. Adidas predicts that it will have produced 100,000 pairs by end of 2018.

The shoes are developed from the Futurecraft designs launched in 2015, which featured 3D-printed elements in its soles. A later version also incorporated uppers made from biodegradable Biosteel fibres that replicate natural silk.

Adidas came in at number 18 on the first Dezeen Hot List – a ranking of the most newsworthy players in the architecture and design industry.

The company's experiments with materials have also resulted in trainers and swimwear made from recycled ocean plastic.