Advances in digital design and mass timber are leading us to "a new Bauhaus"

The combination of digital technology and mass timber is revolutionising the way we design and build buildings, according to the panellists of our recent talk with Dassault Systèmes.

Titled How Virtual Mass Timber Extends and Improves Real Mass Timber, the talk explored how new digital design tools and material innovations are converging to create more sustainable buildings and cities.

In the talk, Jerry Jackson and Nuri Miller of software company Dassault Systèmes and architect Kirsten Haggart argued that the convergence of mass timber with a design approach called design for manufacture and assembly (DfMA) is enabling architects, engineers and contractors to create buildings that are more affordable, higher quality and better for the environment.

"I don't think it's too ambitious to say, it's like a new Bauhaus that we're approaching at the moment," said Haggart in the talk.

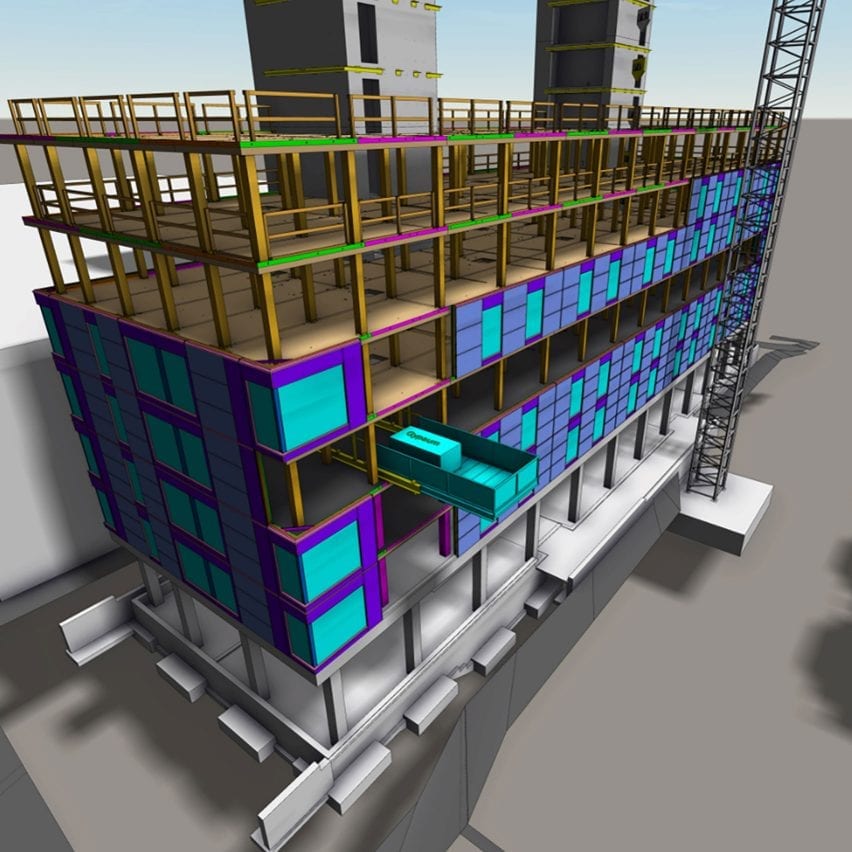

Above: The talk explored how new digital design tools and materials such as CLT are converging. Top: Brock Commons Tallwood House was the tallest mass-timber building in the world when it completed in 2016

Haggart is senior associate at London architecture firm Waugh Thistleton, which has pioneered the use of cross-laminated timber (CLT) in buildings. The firm claims its Dalston Works office building was the largest CLT building in the world when it was completed in 2017.

CLT comprises layers of wood glued together at right angles and is one of the best-known types of mass timber, a broad term used to describe a range of engineered wood products that are strong enough to produce structural panels and beams. Other examples of mass timber include glue-laminated timber (glulam) and laminated veneer lumber (LVL).

"When you're building in timber, your embodied energy levels go right down"

Using mass timber in place of structural materials such as concrete and steel can significantly reduce a building's carbon footprint because the carbon dioxide that trees remove from the atmosphere is stored in the wood.

"When you're thinking about timber, it's recyclable," said Haggart. "But it's also got the added advantage of being renewable as well, which means it has sequestered carbon."

"That is the big thing that makes all the difference. When you're building in timber, your embodied energy levels go right down."

CLT buildings comprise a series of prefabricated modules that are manufactured in a factory and then assembled on-site. According to Haggart, this represents a fundamental change in the way that architects design buildings.

"When you're designing a module, you actually need to design everything much earlier so that once the production line gets going, then there are very few changes, because stops and starts on the production line can have quite big economic problems for the factory," she said.

"It's a completely different way of designing and the way that we are all kind of trained as architects to go through all the RIBA [Royal Institute of British Architects] stages needs to be reviewed."

DfMA can "reduce cost and increase quality"

This is where design for manufacture and assembly (DfMA) comes in. This approach to design, which has been successfully applied to the industrial design and production of cars and other consumer products for years, seeks to make the manufacturing and assembly process as efficient as possible in order to reduce costs.

Mass timber such as CLT lends itself to this approach because the modules are prefabricated. Buildings can also be constructed using far fewer modules than would be required if using a structural material such as steel.

Jackson, who is director of architecture, engineering and construction at Dassault Systèmes, believes that applying DfMA to the design and construction of buildings, what is sometimes referred to as "productisation", can result in a dramatic reduction in cost and increase in quality.

He likens it to what has happened with consumer products such as cars and mobile phones over the years.

"When I was growing up in the 1970s, my economic means weren't that great so I had to get a job at Burger King," he said. "And off a Burger King salary, I definitely could not afford a new car."

"Today, I could reasonably depart from Dassault Systèmes to work at Starbucks, and I could buy a pretty nice Honda Civic with incredible scope and incredible quality. And if you think of mobile phones, look at the scope and quality that you get from a smartphone."

"It's happened so many times and we've experienced it constantly as product buyers in so many different segments of product development," he continued.

"And I do think the work that Waugh Thistleton and others are doing with DfMA and mass timber is phenomenal, because that is the promise."

Dassault Systèmes, which has its roots in developing software for the aviation and automotive industries, offers architects, engineers and contractors a suite of digital tools to enable them to apply DfMA methodologies via it's 3DEXPERIENCE platform.

In particular, Dassault Systèmes’ platform enables the creation of what the brand calls a "Virtual Twin Experience" that allows users to test ideas and real-life scenarios to iterate the design before the construction phase to ensure that the process is as efficient as possible.

The software was used to design and build Brock Commons Tallwood House, an 18-storey student residence at the University of British Columbia by Acton Ostry Architects, which was the world's tallest mass-timber building when it was completed in 2016.

"Virtual worlds extend and improve the real world"

The design for the building was developed using a digital model of the building to test different ways of constructing it.

"This high-fidelity 3D representation and system was really a way to test and virtually build everything for the project down to the CNC code [to fabricate the timber modules]," explained Miller, cloud solution consultant at Dassault Systèmes.

"It gave the ability to really hone in on where everything would fit in the building and how it would all come together."

"This really emphasises for us our belief that virtual worlds extend and improve the real world," he added, claiming that the project was built 70 per cent faster and at less cost than a traditional building.

"We can test many scenarios, we can go through many, many iterations and we can choose the best one."

Industrial processes starting to be applied to architecture at scale

Miller agreed with Haggart that the convergence of new technologies, materials and methodologies could lead to a "new Bauhaus".

The influential twentieth-century design school and movement embraced industrial production but, according to Miller, we're only now starting to be able to apply industrial processes to building at scale.

"If you look at the early modernists, and that idea of the kit of parts, it really goes back to them," he said.

"But it was really just a design philosophy, right? It was just kind of a way to think about the design process."

"Here, we're actually practising that," he continued. "We're really starting to put that into real practice. And we're doing that because of the convergence of all these elements. The technology, the manufacturing, the understanding from other industries. It's really coming together."

Partnership content

This article was written by Dezeen for Dassault Systèmes as part of a partnership. Find out more about Dezeen partnership content here.